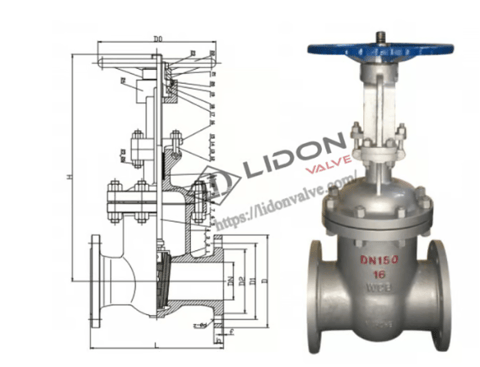

Double Disc Gate Valve

Product Features

| Size Range | DN15~DN1500’╝ł5 inches--600 inches’╝ē |

| Pressure Range | 1.6Mpa--26Mpa |

| Connection Type | Flange |

| Applicable Temperature | -20~1200Ōäā |

| Sealing material | Alloy |

| Body material | Carbon steel,stainless stee! |

| Disc material | Carbon steel,stainless stee |

| O Pressure test | GB/T13927.API598 |

| Face to Face | GB/T12221 |

| perating Mode | Manual,Pneumatic |

| Model type | Z42H-16C |

he Ceramic Double Disc Gate Valve by LIDON VALVE serves a primary function in handling the feeding and discharge of dry powder in transport pipelines. It utilizes robust toughened ceramic for its shut-off mechanism, ensuring durability and wear resistance. The valve incorporates a pressure self-sealing design and an automatic rotation feature for the valve disc. This innovative construction enhances the wear resistance of the sealing surface during frequent opening and closing cycles with dry powder. As a result, the valve not only meets high sealing performance standards but also ensures an extended operational lifespan.

|  |

Characteristics

1. Simple structure and easy maintenance

The structure of the double gate valve is relatively simple, consisting of two parallel gates connected to the pipeline through ordinary threads. Therefore, the double gate valve is not only easy to install, but also relatively easy to maintain.

2. Long service life

The sealing surface of the double gate valve is made of metal materials, such as stainless steel, copper alloy, etc., which have been specially treated to have high hardness and wear resistance. Therefore, the service life of double gate valves is relatively long, up to several years.

3. Good sealing performance

The sealing surface of the double gate valve is made of metal material and has good sealing performance. In addition, the double gate valve also has the characteristics of two-way sealing, that is, it has good sealing performance in both directions. Therefore, double gate valves are widely used in the field of fluid control.

4. Easy to operate

The operation of the double gate valve is relatively simple. You only need to rotate the valve cover to complete the switching operation. In addition, the double gate valve can also be automatically controlled electrically or pneumatically to improve production efficiency.

Application

- Cement industry-dry powdersŌĆÖ conveying and dumping.

- Dressing works-dry powder materialsŌĆÖ selection and conveying.

| No. | Name and specification | Material | Remark | NO. | Name and specification | Material | Remark |

| 1 | Valve body | WCB | 14 | Round pin | 35 | Standard Parts | |

| 2 | Wedge | WCB+D507Mo | 15 | Cotter pin 3.2X20 | 35 | Standard Parts | |

| 3 | Valve seat | WCB+D507Mo | 16 | Packing gland | WCB | ||

| 4 | Movable shaft | 2Cr13 | 17 | Thrust ball bearing | Gcr15 | Standard Parts | |

| 5 | Valve stem | 2Cr13 | 18 | Stem nut | QA19-4 | ||

| 6 | Double stud | 35 | Standard Parts | 19 | Bearing gland | 25 | |

| 7 | Nut | 35 | Standard Parts | 20 | M10 Slotted flat end setting screw M10 | 35 | |

| 8 | Wound gasket | 304+Graphite | 21 | Flat key 10X20 | 45 | Standard Parts | |

| 9 | Bonnet | WCB | 22 | Hand wheel | QT400-17 | ||

| 10 | Back seal | 304 | 23 | Round nut | 45 | Standard Parts | |

| 11 | Filler | Flexible graphite | 24 | Bracket | WCB | ||

| 12 | Nut | 35 | Standard Parts | 25 | Double stud | 35 | Standard Parts |

| 13 | Knuckle bolt | 35 | Standard Parts | 26 | Nut | 35 | Standard Parts |

Certificates

Our manufacturing heavy industry expertise and commitment to quality have earned us a range of industry certificates, showcasing our dedication to excellence. With these certifications, we demonstrate our compliance with rigorous standards, ensuring that our products are of the highest quality and meet all necessary regulatory requirements. Our advantages lie not only in our certifications but also in our advanced production capabilities, state-of-the-art machinery, and skilled workforce. By leveraging cutting-edge technology and employing experienced professionals, we consistently deliver products that excel in performance, durability, and reliability. Additionally, our commitment to innovation allows us to stay ahead of the competition, constantly improving our processes and products to meet evolving market demands. With a strong emphasis on customer satisfaction, we strive to provide tailored solutions, prompt delivery, and exceptional after-sales service. Trust in our industry-leading expertise and certified products to gain a competitive edge in the manufacturing heavy industry.