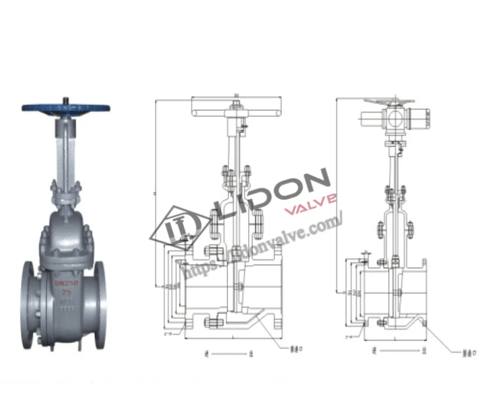

Scum Gate Valve

| Name | Material | Name | Material |

| body | WCB | padding | flexbile graphite |

| seat | Composite engineering ceramics | packing gland | 2Cr13 |

| disc | WCB+ceramics | stem | 1Cr13 |

| nut | 25 | stem nut | bronze |

| stud | 35CrMoVA | hand wheel | KTII350-10 |

Scum Gate Valve

Structure and characteristics

1. The materials are carefully selected, complying with relevant domestic and foreign standards, and the surface quality of the materials is high.

2. The sealing material is a wear-resistant alloy, which has strong wear resistance, erosion resistance, scratch resistance, low friction and reliable sealing.

3. The middle flange is connected with flange bolts, and both ends of the branch pipe are connected by flanges.

4. The opening and closing parts are forcedly sealed by semi-sealing pairs and have excellent performance.

5. The outlet flow channel of the valve body has a reasonable linear shape, no residue, flexible opening and closing, and no obstruction.

6. The valve stem has been tempered and surface nitrided, and has good corrosion resistance, scratch resistance and wear resistance.

7. Medium and large diameters are equipped with thrust ball bearings and impact handwheels, making it easy to open and close.

Product Standard

- Design and manufacture according to: GB/T 12234

- Face to face: GB/T 12221

- Flange standard: JB/T 79

- Inspection and testing: JB/T 9092

- Preesure-Temperature: GB/T 9131

- Product identification: GB/T 12220

|

|

High-Quality Scum Gate Valve for Efficient Waste ManagementIntroducing our top-of-the-line Scum Gate Valve, a revolutionary product designed to enhance the efficiency of waste management systems. With its exceptional features and durable construction, this gate valve is the perfect choice for various industrial and commercial applications. Let's delve into the unique aspects and benefits of this remarkable product. Durable Construction for Long-Lasting PerformanceOur Scum Gate Valve is crafted using high-quality materials, ensuring long-lasting performance and reliability. The valve body is made from corrosion-resistant stainless steel, preventing any deterioration caused by harsh chemicals or environmental conditions. The sturdy construction guarantees that this gate valve can withstand heavy-duty usage, making it ideal for demanding industrial applications. Efficient Flow Control for Optimal Waste ManagementFeaturing a precise flow control mechanism, our Scum Gate Valve enables efficient waste management by allowing operators to regulate the flow of scum, sludge, and other waste materials. This level of control ensures that the waste management process is optimized, preventing overflow or underflow issues. The valve's smooth operation and tight sealing mechanism further enhance its effectiveness in managing waste flow. Wide Range of Sizes and ConfigurationsWe understand that every waste management system is unique, which is why our Scum Gate Valve is available in a wide range of sizes and configurations. Whether you need a small valve for a compact system or a larger valve for a high-capacity setup, we have the perfect solution to fit your specific requirements. Our valves are also available in various connection types, ensuring compatibility with different piping systems. Versatile Applications for Various IndustriesOur Scum Gate Valve is highly versatile and finds applications in a wide range of industries. Whether you need to manage waste in wastewater treatment plants, industrial facilities, or commercial establishments, this valve is the perfect solution. Its adaptability and exceptional performance make it a reliable choice for professionals across different sectors. Exceptional Durability for Harsh EnvironmentsOperating in harsh environments is no challenge for our Scum Gate Valve. Its robust construction and corrosion-resistant materials make it highly durable, even in the most demanding conditions. Whether exposed to extreme temperatures, chemicals, or abrasive substances, this valve will continue to deliver optimal performance, ensuring uninterrupted waste management. Industry-Leading Customer SupportAs a customer-centric company, we take pride in providing industry-leading customer support. Our dedicated team of experts is ready to assist you with any queries or concerns regarding our Scum Gate Valve. From selecting the right size and configuration to troubleshooting and maintenance advice, we are here to ensure your experience with our product is exceptional. Scum Gate Valve, waste management, flow control, efficient, durable construction, versatile applications, durability, customer supportHigh-Quality Scum Gate Valve for Efficient Waste Management | Buy NowEnhance your waste management system with our high-quality Scum Gate Valve. Durable, efficient, and easy to install, this valve offers precise flow control and reliable leakage prevention. Choose the perfect size and configuration for your needs and enjoy exceptional performance in various industries. Industry-leading customer support ensures a hassle-free experience. Buy now and optimize your waste management process. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Certificates

Our manufacturing heavy industry expertise and commitment to quality have earned us a range of industry certificates, showcasing our dedication to excellence. With these certifications, we demonstrate our compliance with rigorous standards, ensuring that our products are of the highest quality and meet all necessary regulatory requirements. Our advantages lie not only in our certifications but also in our advanced production capabilities, state-of-the-art machinery, and skilled workforce. By leveraging cutting-edge technology and employing experienced professionals, we consistently deliver products that excel in performance, durability, and reliability. Additionally, our commitment to innovation allows us to stay ahead of the competition, constantly improving our processes and products to meet evolving market demands. With a strong emphasis on customer satisfaction, we strive to provide tailored solutions, prompt delivery, and exceptional after-sales service. Trust in our industry-leading expertise and certified products to gain a competitive edge in the manufacturing heavy industry.