Chemical Valves

Chemical pipeline equipment is the lifeline of normal operations for chemical enterprises. In the routine production and maintenance of pipeline equipment, corrosion prevention is particularly crucial. It effectively prevents the occurrence of faults in pipeline equipment, thereby reducing maintenance costs and enhancing economic benefits. The main cause of corrosion in pipeline equipment is the reaction of harmful substances such as SO2, H2S, CO2 present in the production process with the structural materials of the pipeline equipment in high-temperature and humid environments, ultimately leading to corrosion of the pipeline equipment. Therefore, ceramic valves are especially important in chemical systems. We recommend the use of ceramic ball valves, which can effectively protect the normal operation of chemical pipelines

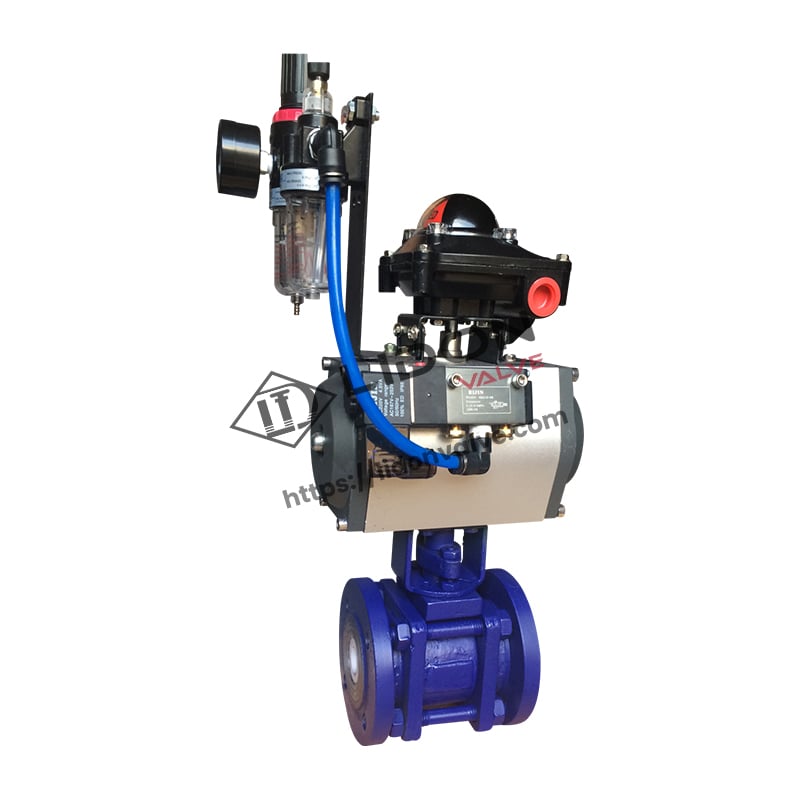

The Chemical Valves serves multiple critical functions within a fluid transportation system. Primarily, it acts as a debris filter, safeguarding pipelines from potential damage by efficiently capturing and preventing the passage of unwanted particles. Additionally, the valve plays a crucial role in controlling the flow of various fluids, including oils, water, and acid, ensuring a smooth and regulated movement through the pipeline.The construction of ceramic ball valves is similar to that of ordinary ball valves. However, in chemical systems where corrosive fluids are common, their fully lined ceramic structure plays an extraordinary role in this system.