Ceramic Slag Check Valve

Characteristics:

1. All parts in contact with the medium are structural ceramic materials with extremely high chemical stability and hardness (Rockwell hardness HRC90), second only to diamond

2. The good wear resistance of ceramics makes this valve durable, highly reliable, and has a long service life, which is 2-4 times that of titanium alloy valves and Monel valves: This valve has extremely high wear resistance and corrosion resistance, erosion resistance and good heat insulation; can be used for high-hardness granular media; can be used in various complex working conditions, more professional: can be used in soft particles but corrosive media; low cost, long service life, cost-effective high;

3. Wear-resistant ceramic slagging check valves are mainly used in industrial fields such as electric power, petroleum, chemical industry, metallurgy, mining, sewage treatment, etc. They are especially outstanding when facing severe working conditions such as high wear, strong corrosion, high temperature, and high pressure. The characteristic of ceramic valves is their long service life. The performance-price ratio of ceramic valves is far superior to that of other similar metal valves.

| Nominal pressure CLASS |

Nominal diameter IN(mm) |

Dimension(mm) | Weight (kg) |

|||||||

| L | D | D1 | D2 | b | f | Z- φd | H | |||

| 150LB | 200 | 495 | 343 | 298.5 | 270 | 28.5 | 2 | 8-22 | 345 | 140 |

| 250 | 622 | 406 | 362 | 324 | 31 | 2 | 12-25 | 412 | 226 | |

| 300 | 698 | 483 | 432 | 381 | 32 | 2 | 12-25 | 468 | 306 | |

| 350 | 787 | 534 | 476.5 | 413 | 35 | 2 | 12-29 | 524 | 426 | |

| 400 | 900 | 597 | 539.5 | 470 | 37 | 2 | 16-29 | 600 | 570 | |

| 450 | 918 | 635 | 578 | 533 | 40 | 2 | 16-32 | 670 | 775 | |

| 500 | 978 | 699 | 635 | 584 | 43 | 2 | 20-32 | 750 | 970 | |

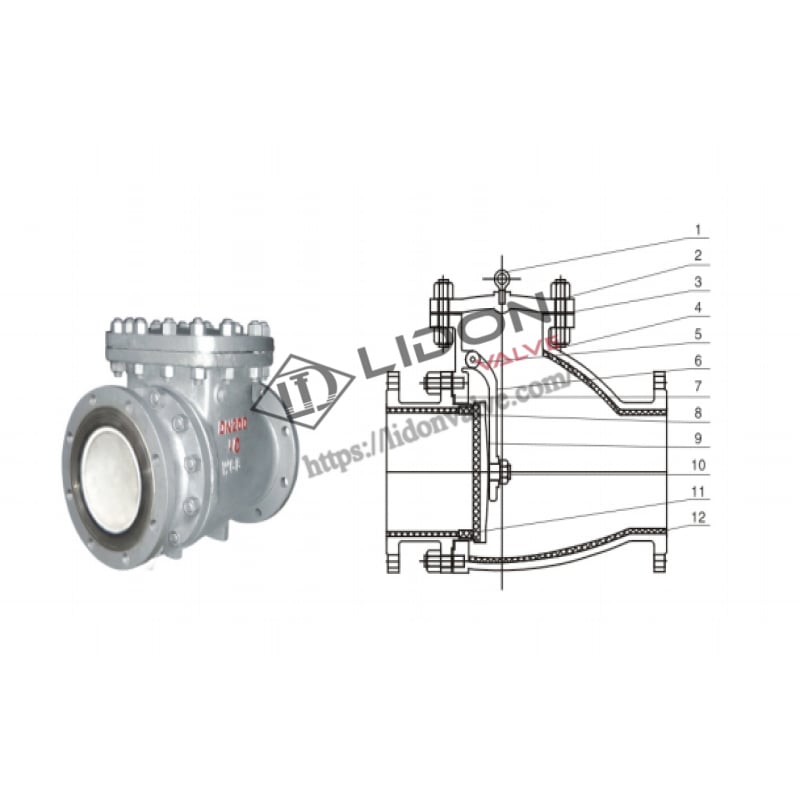

| No. | Name | Material | No. | Name | Material | |||||||

| 1 | fishing ring | 35 | 7 | metal flexible graphite | Flexible Graphite | |||||||

| 2 | nut | 35 | 8 | sealed joint | Engineering Ceramics | |||||||

| 3 | upper cover | WCB | 9 | Valve Plate | WCB+Engineering Ceramics | |||||||

| 4 | Stud | 35CrMoA | 10 | Positioning nut | 35 | |||||||

| 5 | Cylindrical cutting | 2Cr13 | 11 | Sealing surface | Engineering Ceramics | |||||||

| 6 | springboard | WCB | 12 | valve body | WCB+Engineering Ceramics | |||||||

| Nominal pressure PN |

Woking pressure under normal temperature Max. |

The shell testing | Air seal test pressure | High-pressure seal test pressure | ||||

| 1.6 | 1.6 | 2.4 | 0.6 | 1.76 | ||||

| 2.5 | 2.5 | 3.8 | 0.6 | 2.75 | ||||

| 4.0 | 4.0 | 6.0 | 0.6 a |

4.4 | ||||

| 6.4 | 6.4 | 9.6 | 0.6 | 7.1 | ||||

| Class150 | 2.0 | 3.0 | 0.6 | 2.2 | ||||

| Class300 | 5.0 | 7.5 | 0.6 | 5.5 | ||||

| Design reference | GB | API | ASME | |||||

| Design standard | GB/T12237 | API6D | ASME B16.34 | |||||

| Structural length | GB/T12221 | API 6D | ASME B16.10 | |||||

| Flanged ends | GB/T9113 JB/T79 |

ASME B16.5、B16.47 | ||||||

| Test & inspection | JB/T9092 | API 6D | API 598 | |||||

Ceramic Slag Check Valve: Ensuring Efficient Flow and Reliable Performance

In the world of industrial applications, the Ceramic Slag Check Valve stands as a reliable and indispensable component. This state-of-the-art valve is designed to regulate the flow of fluid or gas, allowing it to move in one direction while preventing any backflow. With its exceptional durability and innovative features, the Ceramic Slag Check Valve is perfect for a wide range of heavy-duty applications, including those involving slag and other abrasive materials.

Efficient Flow Control

With its advanced design, the Ceramic Slag Check Valve offers efficient flow control, allowing for smooth and uninterrupted operations. The valve's unique mechanism ensures that fluid or gas can flow freely in one direction while preventing any backflow. This feature is particularly important in applications where the prevention of reverse flow is critical for safety and process efficiency.

Minimized Pressure Loss

The Ceramic Slag Check Valve is engineered to minimize pressure loss, optimizing overall system performance. With its streamlined design and precision manufacturing, this valve ensures minimal resistance to fluid or gas flow, resulting in improved energy efficiency and reduced operating costs. By reducing pressure loss, the Ceramic Slag Check Valve allows systems to operate at their full potential, maximizing productivity and reliability.

Enhanced Sealing and Leak Prevention

When it comes to sealing and leak prevention, the Ceramic Slag Check Valve sets a new standard of excellence. Its innovative sealing mechanism, combined with its high-quality ceramic materials, creates a tight and reliable seal, preventing any unwanted leaks or fluid loss. This feature is crucial in applications where leakage can lead to environmental contamination, safety hazards, or loss of valuable resources.

Smooth Operation and Low Maintenance

The Ceramic Slag Check Valve offers smooth and reliable operation, ensuring a hassle-free experience for operators. Its well-designed mechanism and high-quality components enable smooth opening and closing actions, reducing the risk of jamming or malfunction. Additionally, the valve's durable construction minimizes the need for frequent maintenance, saving time and costs for operators.

Easy Installation and Integration

Installing the Ceramic Slag Check Valve is a breeze, thanks to its user-friendly design and compatibility with various piping systems. This valve comes with clear installation instructions, allowing for quick and hassle-free setup. Moreover, it can be easily integrated into existing systems without requiring any major modifications or additional equipment, providing a cost-effective solution for upgrading or replacing valves.

Cost-Effective Solution

The Ceramic Slag Check Valve offers a cost-effective solution for industries seeking reliable flow control and long-term savings. Its durability and low maintenance requirements result in reduced downtime and maintenance costs. Additionally, its efficient flow control and minimized pressure loss contribute to energy savings and improved overall system efficiency. With the Ceramic Slag Check Valve, businesses can achieve optimal performance while keeping costs in check.

Certificates

Our manufacturing heavy industry expertise and commitment to quality have earned us a range of industry certificates, showcasing our dedication to excellence. With these certifications, we demonstrate our compliance with rigorous standards, ensuring that our products are of the highest quality and meet all necessary regulatory requirements. Our advantages lie not only in our certifications but also in our advanced production capabilities, state-of-the-art machinery, and skilled workforce. By leveraging cutting-edge technology and employing experienced professionals, we consistently deliver products that excel in performance, durability, and reliability. Additionally, our commitment to innovation allows us to stay ahead of the competition, constantly improving our processes and products to meet evolving market demands. With a strong emphasis on customer satisfaction, we strive to provide tailored solutions, prompt delivery, and exceptional after-sales service. Trust in our industry-leading expertise and certified products to gain a competitive edge in the manufacturing heavy industry.