Ceramic Scum Valve

• Sizes Ranges from 5″ thru 600″, DN15 thru DN1500

• Pressure Ratings: PN6, PN10, PN16, ANSI # Cl125 & Cl150

• Ends Connections available in Wafer ends, Semi-lug, Lug type, or Double Flanged,

• Materials: Cast Iron, Carbon Steel, Stainless Steel, Duplex SS, Al-bronze, or other special alloys.

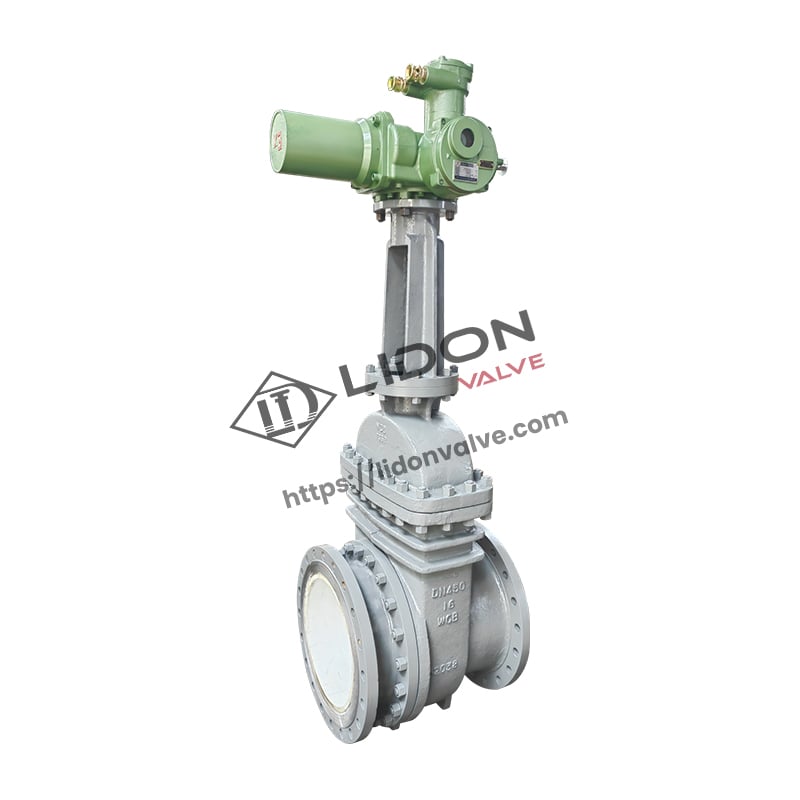

• Operation: Manually lever or gear, Electric, Pneumatic or Hydraulic, Electric

• Standard compliance: MSS SP-81, ASME B16.10, ASME B16.5, ASME B16.47, ASME B16.34, AS 2129 T/D or T/E, BS 4504 T/D OR T/E, MSS SP-55, EN 1092

• Compact design, one piece integral cast body, chest and lugs

• Integral cast in gate wedges minimize flow obstructions

• High quality gate finish for optimum sealing

• High flow rates with low pressure drops

• Robust and compact mounting yoke made of steel with self aligning gland box

• Gland packing made of PTFE impregnated Fibres

Characteristics:

1. Suitable for petroleum, chemical industry, metallurgy, mining, electric power, coal conveying plants, cement plants, water treatment, and other industries.

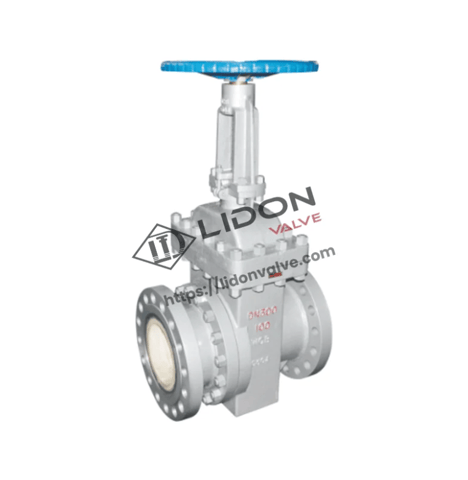

2. The gate and valve seat sealing surface materials are made of structural ceramics, which are resistant to wear, corrosion, high-temperature creep, and thermal shock, achieving a long life and maintenance-free.

3. The lower part of the valve body of the slag discharge valve is equipped with a slag discharge port. When closed, due to the pressure of the pipeline, it rushes to the slag discharge port to completely discharge the slag. There will be no ash left at the bottom of the valve, making the gate completely sealed.

4. Applicable medium: ash-slag-water mixture, slag-water ratio >1:6, maximum particle size ≤50mm.

| Nominal pressure CLASS |

Nominal diameter IN(mm) |

Dimension(mm) | Weight(kg) | |||||||||

| f | f2 | z-d | H | H1 | H2 | Do | Manual operation | power-driven | ||||

|

150LB |

2 | 2 | 4-19 | 335 | 385 | 640 | 200 | 34 | 88 | |||

| 21/2 | 2 | 4-19 | 360 | 435 | 670 | 220 | 38 | 92 | ||||

| 3 | 2 | 4-19 | 415 | 495 | 720 | 240 | 46 | 100 | ||||

| 4 | 2 | 8-19 | 490 | 590 | 790 | 260 | 70 | 114 | ||||

| 5 | 2 | 8-22 | 552 | 677 | 852 | 280 | 100 | 164 | ||||

| 9 | 2 | 8-22 | 600 | 755 | 900 | 300 | 125 | 179 | ||||

| 8 | 2 | 8-22 | 780 | 980 | 1070 | 350 | 207 | 267 | ||||

| 10 | 2 | 12-25 | 860 | 1110 | 1150 | 400 | 279 | 339 | ||||

| 12 | 2 | 12-25 | 1010 | 1310 | 1300 | 450 | 392 | 492 | ||||

| 14 | 2 | 12-29 | 1160 | 1510 | 1450 | 500 | 537 | 665 | ||||

| 16 | 2 | 16-29 | 1400 | 1800 | 1775 | 550 | 680 | 812 | ||||

| 18 | 2 | 16-32 | 1500 | 1950 | 1875 | 600 | 850 | 982 | ||||

| 20 | 2 | 20-32 | 1600 | 2100 | 1968 | 700 | 1100 | 1345 | ||||

| 24 | 2 | 20-35 | 1910 | 2510 | 2295 | 700 | 1700 | 2180 | ||||

|

300LB |

2 | 2 | 4 | 8--18 | 350 | 400 | 640 | 240 | 34 | 88 | ||

| 21/2 | 2 | 4 | 8--22 | 385 | 460 | 670 | 280 | 38 | 92 | |||

| 3 | 2 | 4 | 8--22 | 443 | 538 | 720 | 320 | 68 | 122 | |||

| 4 | 2 | 4.5 | 8--22 | 512 | 630 | 800 | 360 | 98 | 152 | |||

| 5 | 2 | 4.5 | 8-22 | 627 | 768 | 905 | 360 | 150 | 204 | |||

| 6 | 2 | 4.5 | 12--22 | 691 | 862 | 966 | 400 | 240 | 300 | |||

| 8 | 2 | 4.5 | 12--26 | 840 | 1059 | 1100 | 450 | 320 | 380 | |||

| 10 | 2 | 4.5 | 16-30 | 994 | 1270 | 1220 | 500 | 390 | 490 | |||

| 12 | 2 | 4.5 | 16-33 | 1172 | 1502 | 1527 | 550 | 600 | 703 | |||

| 14 | 2 | 5 | 20-33 | 1300 | 1480 | 1665 | 600 | 820 | 928 | |||

| 16 | 2 | 5 | 20-36 | 1502 | 1937 | 1870 | 700 | 1250 | 1382 | |||

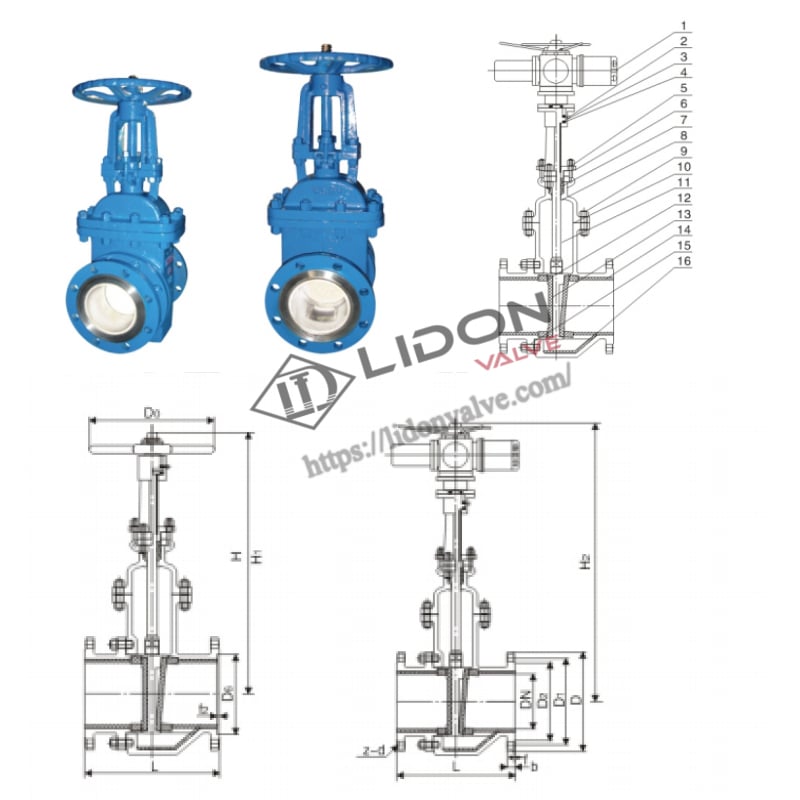

| No. |

Name |

Material | No. | Name | Material | |||||||

| 1 | Electric Actuator | 9 | screw | 30 | ||||||||

| 2 | Glib | Q235A | 10 | Composite gasket | ||||||||

| 3 | Valve nut | Aluminum bronze | 11 | Stem | 2Cr13 | |||||||

| 4 | Surface bearing | 12 | Sealing surface | WCB+Engineering Ceramics | ||||||||

| 5 | Cylindrical cutting | 35 | 13 | gate | WCB+Engineering Ceramics | |||||||

| 6 | Packing plate | WCB | 14 | Connector | WCB+Engineering Ceramics | |||||||

| 7 | Flexible Graphite | 15 | valve body | WCB+Engineering Ceramics | ||||||||

| 8 | upper seal | Stellite6 | 16 | Slag discharge port | WCB+Engineering Ceramics | |||||||

| Nominal pressure PN |

Woking pressure under nomal iemperatue Max. |

The shell testing | Air seal test pressure | High-pressure seal test pressure |

||||

| 1.6 | 1.6 | 2.4 | 0.6 | 1.76 | ||||

| 2.5 | 2.5 | 3.8 | 0.6 | 2.75 | ||||

| 4.0 | 4.0 | 6.0 | 0.6 | 4.4 | ||||

| 6.4 | 6.4 | 9.6 | 0.6 | 7.1 | ||||

| Class150 | 2.0 | 3.0 | 0.6 | 2.2 | ||||

| Class300 | 5.0 | 7.5 | 0.6 | 5.5 | ||||

| Design reference | GB | API | ASME | |||||

| Design standard | GB/T12237 | API 6D | ASME B16.34 | |||||

| Structural length | GB/T12221 | API6D | ASME B16.10 | |||||

| Flanged ends | GB/T9113 JB/T79 |

ASME B16.5、B16.47 | ||||||

| Test& inspection | JB/T9092 | API6D | API 598 | |||||

Introducing the Ceramic Scum Valve: The Ultimate Solution for Clean and Efficient Water Systems

Ceramic Scum Valve: The Ultimate Solution for Clean and Efficient Water Systems. Discover the Ceramic Scum Valve, a revolutionary product designed to enhance the cleanliness and efficiency of water systems. Explore its unique features and benefits.

1. Say Goodbye to Scum Build-Up with the Ceramic Scum Valve

The Ceramic Scum Valve is specifically engineered to combat one of the most common issues in water systems: scum build-up. With its innovative design, this valve effectively prevents scum from accumulating in pipes and tanks, ensuring a cleaner and more efficient water flow.

When scum build-up occurs, it can lead to clogged pipes, reduced water pressure, and even potential damage to the entire water system. The Ceramic Scum Valve eliminates these problems, providing a reliable solution for maintaining optimal water flow.

2. Unleash the Power of Ceramic Technology

The Ceramic Scum Valve harnesses the power of advanced ceramic technology to deliver exceptional performance. Made from high-quality ceramic materials, this valve offers superior durability and longevity, ensuring years of reliable service.

Ceramic is known for its resistance to corrosion, wear, and chemical damage, making it the perfect material for water system components. With the Ceramic Scum Valve, you can confidently enjoy a maintenance-free solution that will stand the test of time.

3. Easy Installation and Compatibility

Installing the Ceramic Scum Valve is a breeze, thanks to its user-friendly design. Whether you're a professional plumber or a DIY enthusiast, you can easily incorporate this valve into your existing water system without any hassle.

Furthermore, the Ceramic Scum Valve is compatible with a wide range of pipes and tanks, making it a versatile choice for various applications. Simply choose the appropriate size and connect the valve to experience its immediate benefits.

4. Enhanced Water Quality

With the Ceramic Scum Valve in place, you can expect an improvement in water quality like never before. This valve effectively filters out impurities and contaminants, ensuring that the water flowing through your system is clean and safe for consumption.

Whether you're using water for drinking, cooking, or bathing, the Ceramic Scum Valve provides an extra layer of protection by removing unwanted particles and pollutants. Say goodbye to concerns about water quality and enjoy peace of mind with this remarkable product.

5. Energy Efficiency at its Finest

By preventing scum build-up and ensuring a smooth water flow, the Ceramic Scum Valve promotes energy efficiency in your water system. With reduced friction and improved water circulation, you can save on energy costs and contribute to a greener environment.

Traditional valves often cause unnecessary strain on water pumps and heaters, leading to increased energy consumption. The Ceramic Scum Valve eliminates these inefficiencies, allowing you to enjoy significant energy savings without compromising performance.

6. Trust in Quality and Reliability

When it comes to your water system, quality and reliability are paramount. The Ceramic Scum Valve is backed by extensive testing and quality assurance, ensuring that it meets the highest industry standards.

Rest assured that this valve is designed to withstand the rigors of everyday use and deliver consistent performance. With the Ceramic Scum Valve, you can trust in its quality and reliability for years to come.

7. Customer Satisfaction Guaranteed

Your satisfaction is our top priority. We stand behind the Ceramic Scum Valve with a comprehensive warranty and dedicated customer support. If you have any questions or concerns, our team is ready to assist you every step of the way.

Join countless satisfied customers who have experienced the benefits of the Ceramic Scum Valve. Invest in this innovative solution today and enjoy a cleaner, more efficient water system.

Certificates

Our manufacturing heavy industry expertise and commitment to quality have earned us a range of industry certificates, showcasing our dedication to excellence. With these certifications, we demonstrate our compliance with rigorous standards, ensuring that our products are of the highest quality and meet all necessary regulatory requirements. Our advantages lie not only in our certifications but also in our advanced production capabilities, state-of-the-art machinery, and skilled workforce. By leveraging cutting-edge technology and employing experienced professionals, we consistently deliver products that excel in performance, durability, and reliability. Additionally, our commitment to innovation allows us to stay ahead of the competition, constantly improving our processes and products to meet evolving market demands. With a strong emphasis on customer satisfaction, we strive to provide tailored solutions, prompt delivery, and exceptional after-sales service. Trust in our industry-leading expertise and certified products to gain a competitive edge in the manufacturing heavy industry.