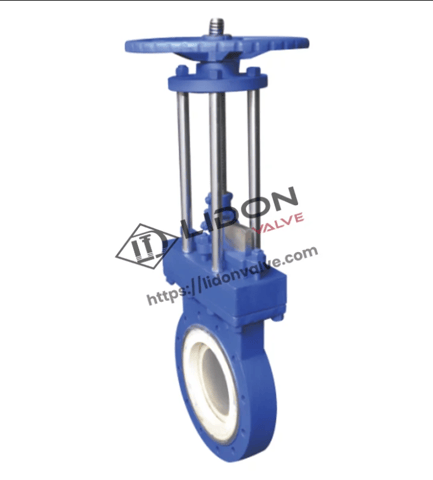

Ceramic Knife Gate Valve

| Size Range | DN15--DN1500,5 Inches--600 Inches |

| Pressure Range | 1.6Mpa--26Mpa |

| Applicable Temperature | 0~200℃ |

| Sealing material | Flange , wafer |

| Body material | Engineering ceramics |

| Disc material | WCB,CF8,CF8M,CF3M |

| Pressure test | GB/T13927,API598 |

| Face to Face | GB/T12221,ASME B16.10 |

| perating Mode | GB/T12224,ASME B16.34 |

| Model type | PZ73TC-16C |

LIDON VALVE's Ceramic Knife Gate Valves, also recognized as slurry gate valves, are characterized by a straightforward design. They effectively isolate mediums containing solid particles and fibers. In contrast to conventional metal-seated knife gate valves, which may erode easily when dealing with extremely hard particles or aggressive mediums, ceramic knife gate valves prove highly suitable. Their resilience makes them ideal for handling mediums that include fibers and resilient solid particles.

|

|

Characteristics:

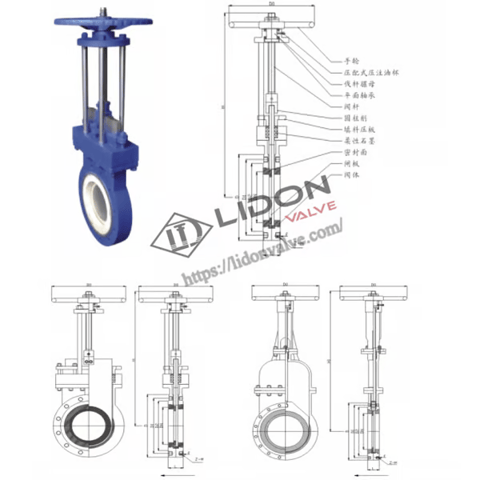

1. Sealing surface materials: structural ceramics or super-hard surface alloy materials.

2. It is suitable for gas and solid mixed media such as cinder and ash. The gate, valve seat and flow channel are made of structural ceramic materials, which are wear-resistant and have a long life.

3. Excellent sealing performance, and the sealing surface can be repaired.

4. The imported valve seat can be used as a dust scraper and can be closed freely even in the presence of dust.

5. The valve body cavity structure completely avoids the problems of jamming and dust accumulation.

6. Driving mode: manual, pneumatic and electric, etc.

Application

Ceramic Knife Gate Valves are well-suited for conveying systems involving two-phase mediums, either liquid-solid or gas-solid.

- ash, mine residue and coal residue in iron and steel plant

- ash conveying system of power plant

- paper pulp in paper industry

- sewage and slurry in decontamination plant

- the heavy medium system of coal mill.

|

Nominal pressure |

Nominal diameter IN(mm) |

L | D | D1 | D2 | F | Z-M | D0 | H | H1 | Weight (kg) |

||

| 150LB | 2 | 50 | 152 | 120.5 | 92 | 2 | 4-16 | 180 | 380 | 375 | 17 | ||

| 21/2 | 50 | 178 | 139.5 | 105 | 2 | 4-16 | 180 | 402 | 409 | 20 | |||

| 3 | 50 | 190 | 152.5 | 127 | 2 | 8-16 | 220 | 437 | 449 | 25 | |||

| 4 | 50 | 229 | 190.5 | 157 | 2 | 8-16 | 220 | 476 | 510 | 32 | |||

| 5 | 50 | 254 | 216 | 186 | 2 | 8-16 | 280 | 543 | 600 | 40 | |||

| 9 | 60 | 279 | 241.5 | 216 | 2 | 8-20 | 280 | 601 | 680 | 46 | |||

| 8 | 70 | 343 | 298.5 | 270 | 2 | 8-20 | 360 | 730 | 810 | 68 | |||

| 10 | 70 | 406 | 362 | 324 | 2 | 12-20 | 360 | 829 | 935 | 102 | |||

| 12 | 80 | 483 | 432 | 381 | 2 | 12-20 | 400 | 937 | 1114 | 123 | |||

| 14 | 90 | 534 | 476.5 | 413 | 2 | 16-20 | 400 | 1105 | 1261 | 200 | |||

| 16 | 100 | 597 | 539.5 | 470 | 2 | 16-22 | 400 | 1252 | 1417 | 265 | |||

| 18 | 100 | 635 | 578 | 533 | 2 | 20-22 | 530 | 1395 | 1567 | 370 | |||

| 20 | 115 | 699 | 635 | 584 | 2 | 20-22 | 530 | 1488 | 1738 | 450 | |||

| 24 | 120 | 813 | 750 | 692 | 2 | 20-27 | 550 | 1758 | 2018 | 675 | |||

| Name | Material | Name | Material | |||||||

| Valve body、bonnet、Bracket | Carbon steel (WCB), body + ceramic | Sealing the surface of the valve seat | Alumina ceramics | |||||||

| Valve stem, spacer ring | 2Cr13 | Stem nut | Copper alloy | |||||||

| (1)Gate sealing surface | Tungsten carbide injection | filling | YS450F(T) flexible graphite | |||||||

| (2)Gate sealing surface | ceramic | Hand wheel | (QT450-10) Ductile iron | |||||||

| Design reference | GB | API | ASME | ||||

| Design standard | GB/T12237 | API6D | ASME B16.34 | ||||

| Structural length | GB/T12221 | API 6D | ASME B16.10 | ||||

| Flanged ends | GB/T9113 JB/T79 | ASME B16.5、B16.47 | |||||

| Test& inspection | JB/T9092 | API6D | API 598 | ||||

| Nominal pressure PN |

Working pressure under normal temperature Max. |

The shell testing | Air seal test pressure |

High pressure seal test pressure |

|||

| 1.0 | 1.0 | 1.5 | 0.6 | 1.1 | |||

| 1.6 | 1.6 | 2.4 | 0.6 | 1.76 | |||

| Class 150 | 2.0 | 3.0 | 0.6 | 2.2 | |||

Certificates

Our manufacturing heavy industry expertise and commitment to quality have earned us a range of industry certificates, showcasing our dedication to excellence. With these certifications, we demonstrate our compliance with rigorous standards, ensuring that our products are of the highest quality and meet all necessary regulatory requirements. Our advantages lie not only in our certifications but also in our advanced production capabilities, state-of-the-art machinery, and skilled workforce. By leveraging cutting-edge technology and employing experienced professionals, we consistently deliver products that excel in performance, durability, and reliability. Additionally, our commitment to innovation allows us to stay ahead of the competition, constantly improving our processes and products to meet evolving market demands. With a strong emphasis on customer satisfaction, we strive to provide tailored solutions, prompt delivery, and exceptional after-sales service. Trust in our industry-leading expertise and certified products to gain a competitive edge in the manufacturing heavy industry.