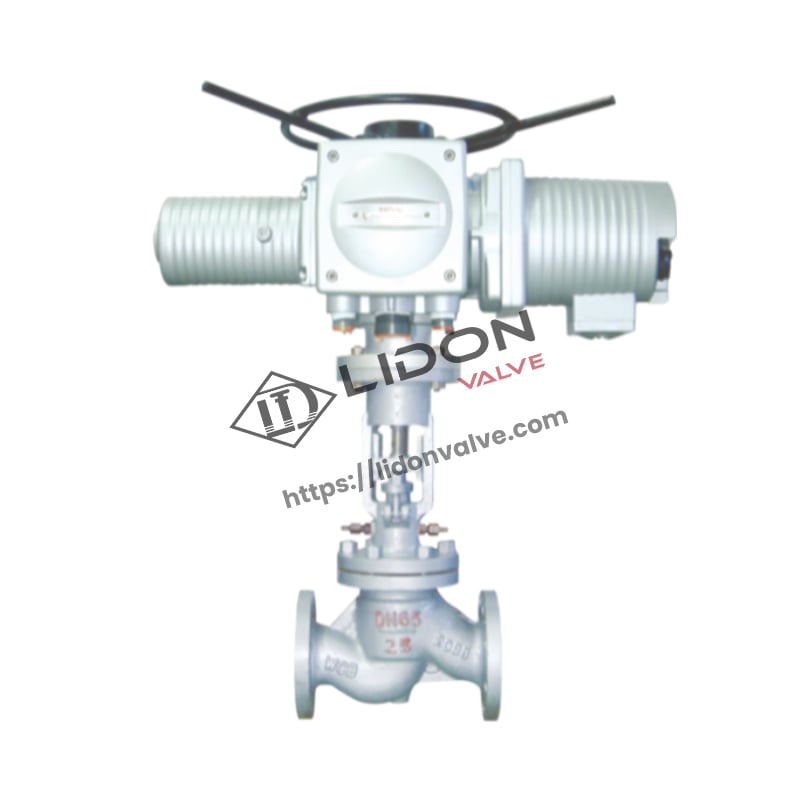

Water-sealed Globe Valve

Characteristics:

1. The materials are carefully selected, complying with relevant domestic and foreign standards, and the materials are of high overall quality.

2. The pairing of sealing pairs is advanced and reasonable, which improves the sealing performance and has a long service life.

3. The stuffing box is designed as a water-sealed structure, and is connected to 0.6 to 1.6 Pa water filler. It has low friction and good sealing. It can isolate the system from the atmosphere and ensure good air tightness. It is an environmentally friendly product.

4. The valve stem has been tempered and surface nitrided, and has good corrosion resistance, scratch resistance and wear resistance.

5. Compact structure, flexible operation and convenient maintenance.

6. The inverted seal is made of stainless steel threaded connection seal or the body is made of austenitic stainless steel surfacing, which ensures reliable sealing. Packing replacement can be carried out without stopping the machine, which is convenient and fast and does not affect the operation of the system.

| Nominal pressure CLASS |

Nominal diameter IN(mm) |

L | D | D1 | D2 | D0 | H | H1 | Weight(kg) | |

| Manual operation | power-driven | |||||||||

| 300LB | 2 | 230 | 165 | 127 | 92 | 200 | 320 | 560 | 19 | 73 |

| 21/2 | 290 | 190 | 149.2 | 105 | 250 | 335 | 575 | 22 | 77 | |

| 3 | 310 | 210 | 168.3 | 127 | 250 | 395 | 685 | 31 | 85 | |

| 4 | 350 | 255 | 200 | 157 | 320 | 415 | 705 | 45 | 105 | |

| 5 | 400 | 280 | 235 | 186 | 320 | 460 | 760 | 75 | 175 | |

| 6 | 480 | 320 | 269.9 | 216 | 350 | 510 | 810 | 95 | 195 | |

| 8 | 600 | 380 | 330.2 | 270 | 550 | 625 | 1010 | 165 | 295 | |

| 10 | 650 | 445 | 387.4 | 324 | 600 | 780 | 1294 | 230 | 475 | |

| 12 | 750 | 520 | 450.8 | 381 | 650 | 855 | 1465 | 325 | 775 | |

| 600LB | 2 | 300 | 165 | 127 | 92 | 240 | 420 | 710 | 40 | 94 |

| 21/2 | 340 | 190 | 149.2 | 105 | 260 | 470 | 760 | 48 | 106 | |

| 3 | 380 | 210 | 168.3 | 127 | 300 | 560 | 860 | 56 | 156 | |

| 4 | 430 | 275 | 215.9 | 157 | 400 | 630 | 930 | 80 | 180 | |

| 5 | 500 | 330 | 266.7 | 186 | 500 | 750 | 1168 | 125 | 257 | |

| 6 | 550 | 355 | 292.1 | 216 | 500 | 850 | 1364 | 200 | 445 | |

| Nominal pressure CLASS |

Nominal diameter IN(mm) |

Standard value | Reference value | ||||||||||

| L | D | D1 | D2 | D6 | b | f | f1 | Z- φd | D0 | H | Weight(kg) | ||

| 150LB | 2 | 230 | 152 | 120.5 | 92 | 19 | 2 | 4-19 | 200 | 325 | 19 | ||

| 21/2 | 290 | 178 | 139.5 | 105 | 22.5 | 2 | 4-19 | 250 | 345 | 22 | |||

| 3 | 310 | 190 | 152.5 | 127 | 23.9 | 2 | 4-19 | 250 | 360 | 33 | |||

| 4 | 350 | 229 | 190.5 | 157 | 23.9 | 2 | 8-19 | 320 | 370 | 18 | |||

| 5 | 400 | 254 | 216 | 186 | 23.9 | 2 | 8-22 | 320 | 480 | 85 | |||

| 9 | 480 | 279 | 241.5 | 216 | 25.4 | 2 | 8-22 | 320 | 598 | 105 | |||

| 8 | 600 | 343 | 298.5 | 270 | 28.5 | 2 | 8-22 | 400 | 702 | 178 | |||

| 10 | 650 | 406 | 362 | 324 | 31 | 2 | 12-25 | 400 | 782 | 446 | |||

| 12 | 750 | 483 | 432 | 381 | 32 | 2 | 12-25 | 500 | 880 | 456 | |||

| 300LB | 2 | 230 | 165 | 127 | 92 | 88 | 22.7 | 2 | 4 | 8--18 | 200 | 350 | 23 |

| 21/2 | 290 | 190 | 149.2 | 105 | 110 | 25.9 | 2 | 4 | 8--22 | 250 | 400 | 28 | |

| 3 | 310 | 210 | 168.3 | 127 | 121 | 29 | 2 | 4 | 8--22 | 250 | 430 | 33 | |

| 4 | 350 | 255 | 200 | 157 | 150 | 32.2 | 2 | 4.5 | 8--22 | 320 | 465 | 53 | |

| 5 | 400 | 280 | 235 | 186 | 176 | 35.4 | 2 | 4.5 | 8-22 | 320 | 505 | 93 | |

| 6 | 480 | 320 | 269.9 | 216 | 204 | 37 | 2 | 4.5 | 12--22 | 320 | 611 | 115 | |

| 8 | 600 | 380 | 330.2 | 270 | 260 | 41.7 | 2 | 4.5 | 12--26 | 400 | 722 | 210 | |

| 600LB | 2 | 300 | 165 | 127 | 92 | 88 | 25.4 | 7 | 4 | 8--18 | 280 | 414 | 49 |

| 21/2 | 340 | 190 | 149.2 | 105 | 110 | 28.6 | 7 | 4 | 8--22 | 320 | 464 | 65 | |

| 3 | 380 | 210 | 168.3 | 127 | 121 | 31.8 | 7 | 4 | 8--22 | 400 | 547 | 95 | |

| 4 | 430 | 275 | 215.9 | 157 | 150 | 38.1 | 7 | 4.5 | 8--26 | 450 | 621 | 115 | |

| 5 | 500 | 330 | 266.7 | 186 | 176 | 44.5 | 7 | 4.5 | 8--30 | 450 | 732 | 149 | |

| 6 | 550 | 355 | 292.1 | 216 | 204 | 47.7 | 7 | 4.5 | 12--30 | 500 | 840 | 310 | |

| 8 | 650 | 420 | 249.2 | 270 | 260 | 55.6 | 7 | 4.5 | 12--33 | 550 | 925 | 590 | |

| Test Pressure | PN/MPa | |||||

| 1.0 | 1.6 | 2.5 | 4.0 | 6.4 | 10.0 | |

| Shell Strength test | 1.5 | 2.4 | 3.8 | 6.0 | 9.6 | 15.0 |

| Seal test | 1.1 | 1.8 | 2.8 | 4.4 | 7.0 | 11.0 |

| Back seal test | 1.1 | 1.8 | 2.8 | 4.4 | 7.0 | 11.0 |

| Leak proofnesstest | 0.5~0.7 | |||||

| Main parts materials | ||||||||

| Product classification |

Part name | Applicable temperature |

Applicable medium |

|||||

| Body, Bonnet, yoke |

Valve rod | Wedge、valve clack、Sealing surface | Seating seal face |

Yoke nut | Yoke nut | ≤425 | Water, stem, oil goods non-corrosive gas |

|

|

Carbon steel |

WCB 25 |

1Cr13 or 2Cr13 |

Cr Stainless steel or carbide alloy |

Stainless steel |

Al bronze |

Flexible graphite |

≤540 | |

|

alloy steel |

WC6 Cr5MO1 |

38CrMOAIA 20Cr1Mo1VA |

Cobalt-based alloy | carbide alloy |

||||

Water-sealed Globe Valve: The Perfect Solution for Efficient Flow Control

When it comes to controlling the flow of water in various industrial applications, the Water-sealed Globe Valve is the ultimate choice. This high-quality valve is designed to provide exceptional sealing performance and superior control accuracy, making it a reliable and efficient solution for all your flow control needs.

1. Smooth Operation

The Water-sealed Globe Valve is designed for smooth and efficient operation. Its ergonomic handle allows for easy and comfortable gripping, ensuring smooth and precise adjustments. The valve's internal components are designed to minimize friction and maximize efficiency, allowing for effortless operation and optimal flow control.

2. Safe and Reliable

Safety is a top priority in any flow control system, and the Water-sealed Globe Valve ensures just that. This valve is equipped with safety features that prevent accidental opening or closing, reducing the risk of system damage. Additionally, its reliable sealing mechanism ensures a secure and leak-free seal, avoiding any potential hazards associated with water leakage.

3. Versatile Sizing Options

The Water-sealed Globe Valve is available in a wide range of sizes, allowing you to choose the perfect fit for your specific application. Whether you need a smaller valve for residential use or a larger valve for industrial purposes, this product offers versatile sizing options to accommodate your needs. Its flexibility and adaptability make it a suitable choice for various flow control systems.

4. Cost-Effective Solution

Investing in the Water-sealed Globe Valve is a cost-effective choice for any flow control system. Its durable construction and long lifespan eliminate the need for frequent replacements, saving you money in the long run. Additionally, its efficient control mechanism helps optimize water usage, reducing operational costs and promoting sustainability.

5. Trusted Brand and Excellent Customer Support

When you choose the Water-sealed Globe Valve, you can trust in the reputation and expertise of the brand behind it. Our company is dedicated to providing top-quality products and excellent customer support. We stand behind the reliability and performance of our valves, ensuring your complete satisfaction with your purchase.

Water-sealed Globe Valve, flow control, sealing performance, control accuracy, durability, longevity, easy installation, maintenance, wide range of applications, smooth operation, safe and reliable, versatile sizing options, cost-effective solution, trusted brand, customer support Water-sealed Globe Valve: The Perfect Solution for Efficient Flow Control. The Water-sealed Globe Valve is a high-quality valve that offers unparalleled sealing performance and superior control accuracy. With its durability, versatility, and cost-effectiveness, it is the perfect solution for efficient flow control in various applications.

Certificates

Our manufacturing heavy industry expertise and commitment to quality have earned us a range of industry certificates, showcasing our dedication to excellence. With these certifications, we demonstrate our compliance with rigorous standards, ensuring that our products are of the highest quality and meet all necessary regulatory requirements. Our advantages lie not only in our certifications but also in our advanced production capabilities, state-of-the-art machinery, and skilled workforce. By leveraging cutting-edge technology and employing experienced professionals, we consistently deliver products that excel in performance, durability, and reliability. Additionally, our commitment to innovation allows us to stay ahead of the competition, constantly improving our processes and products to meet evolving market demands. With a strong emphasis on customer satisfaction, we strive to provide tailored solutions, prompt delivery, and exceptional after-sales service. Trust in our industry-leading expertise and certified products to gain a competitive edge in the manufacturing heavy industry.