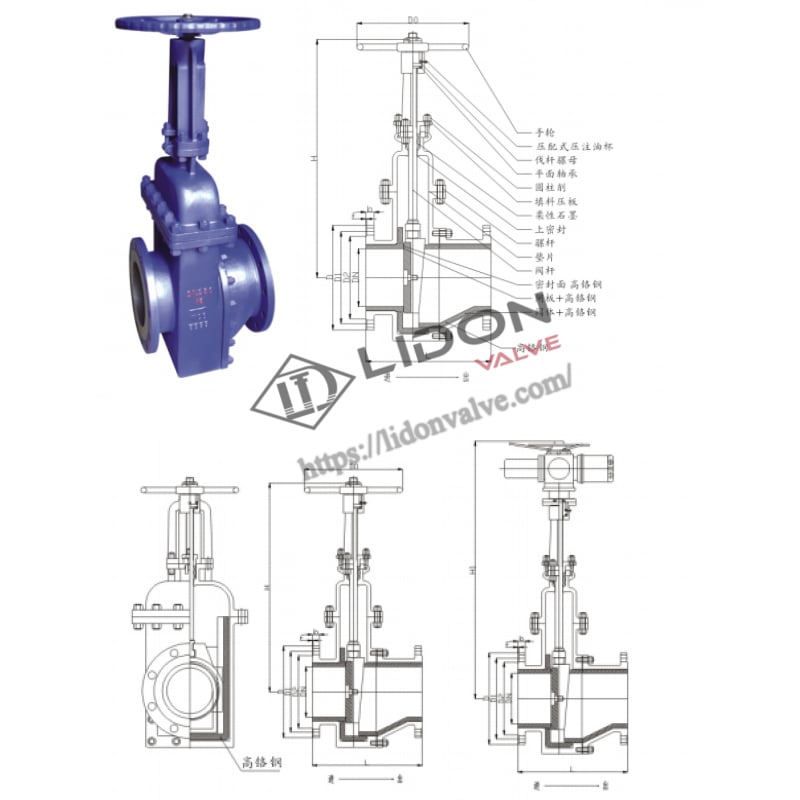

High Chromium Steel Scum Valve

High chromium steel slag discharge valve, slag discharge throttle valve, bolted bonnet, Raised flange.

Design: GB/T 12234-2007.

Body: ASTM A216 WCB

Nominal size: DN15-1500.

Nominal class: PN10.

End Connection: RF.

Face to face: GB/T 12221.

Test and inspection: GB/T 13927.

Characteristics:

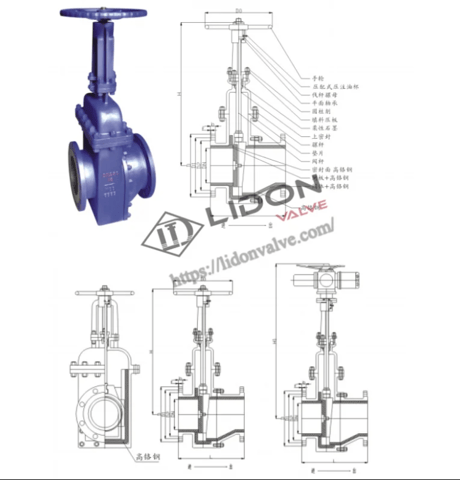

1. The lower part of the slag discharge valve body has a large slag discharge port. The interior of the valve body is lined with high-chromium steel and is adjustable. When closed, the pipeline pressure rushes to the slag discharge port, so the slag is completely discharged without ash. Leave it at the bottom of the valve to seal the gate completely.

2. The selection of materials is superior to ordinary medium and low-pressure valves. The pressure-bearing parts are cast steel, and the sealing surface and valve body are high-chromium steel.

3. The slag discharge gate valve has a parallel double gate structure, which has reliable sealing, easy opening and closing, and easy maintenance.

4. The slag discharge gate valve is lined with high-chromium steel. The thickness of the high-chromium steel is 12mm. The overall hardness reaches more than 60 degrees. It has strong wear resistance and can be used to adjust the flow rate.

5. Wear-resistant slag discharge valve adopts hardness and thickness to achieve wear-resistant effect.

|

|

| Nominal pressure CLASS |

Nominal diameter IN(mm) |

L | D | D1 | D2 | b | Z-d | DO | H | H1 | Weight(kg) | |

| Manual operation | power-driven | |||||||||||

| 150LB | 8 | 400 | 343 | 298.5 | 270 | 28.5 | 8-22 | 400 | 820 | 1136 | 210 | 268 |

| 10 | 450 | 406 | 362 | 324 | 31 | 12-25 | 450 | 969 | 1220 | 270 | 328 | |

| 12 | 500 | 483 | 432 | 381 | 32 | 12-25 | 500 | 1142 | 1527 | 370 | 490 | |

| 14 | 550 | 534 | 476.5 | 413 | 35 | 12-29 | 550 | 1280 | 1665 | 520 | 659 | |

| 16 | 600 | 597 | 539.5 | 470 | 37 | 16-29 | 600 | 1452 | 1870 | 680 | 822 | |

| 18 | 650 | 635 | 578 | 533 | 40 | 16-32 | 700 | 1541 | 1946 | 850 | 992 | |

| 20 | 700 | 699 | 635 | 584 | 43 | 20-32 | 700 | 1676 | 2190 | 1075 | 1325 | |

| 24 | 800 | 813 | 750 | 692 | 48 | 20-35 | 800 | 2000 | 2510 | 1475 | 1725 | |

| Name | Material | Name | Material |

| Valve body, valve cover, bracket | carbon steel(WCB) | Valve seat sealing surface | carbon steel(WCB) |

| Valve stem, spacer ring | Stainless steel(2Cr13) | Stem nut | Stainless steel(2Cr13) |

| Gate sealing surface | carbon steel(WCB)+High chromium steel | filler | carbon steel(WCB)+High chromium steel |

| Slag discharge port and gate surroundings | carbon steel(WCB)+High chromium steel | handwheel | carbon steel(WCB)+High chromium steel |

High Chromium Steel Scum Valve: The Ultimate Solution for Efficient Waste Management

Are you tired of dealing with clogged drainage systems and inefficient waste management processes? Look no further than the High Chromium Steel Scum Valve. This innovative product is designed to revolutionize the way scum is handled in various industrial and municipal applications. With its exceptional durability, high resistance to corrosion, and seamless functionality, this scum valve sets new standards in waste management. Read on to discover the remarkable features that make the High Chromium Steel Scum Valve a game-changer in the industry.

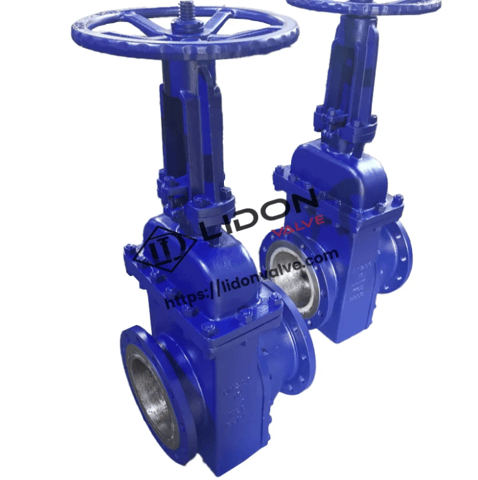

1. Unparalleled Durability for Long-lasting Performance

The High Chromium Steel Scum Valve is crafted using the highest quality materials, ensuring unparalleled durability and long-lasting performance. The valve is constructed from high chromium steel, renowned for its exceptional strength and resistance to wear and tear. This means that the valve can withstand even the harshest conditions, making it an ideal choice for heavy-duty applications.

2. Superior Corrosion Resistance for Longevity

Corrosion is one of the primary concerns when it comes to valves used in waste management systems. However, the High Chromium Steel Scum Valve eliminates this problem with its superior corrosion resistance. The high chromium content in the valve's construction provides a protective barrier against corrosive substances, ensuring its longevity and minimizing the need for frequent maintenance or replacement.

3. Seamless Functionality for Efficient Waste Disposal

The High Chromium Steel Scum Valve boasts a seamless functionality that allows for efficient waste disposal. Its precision engineering ensures smooth operation, enabling the valve to handle large volumes of scum without clogging or causing disruptions in the waste management process. This seamless functionality translates into improved productivity and reduced downtime, making it an invaluable asset in waste treatment facilities.

4. Precise Control for Optimal Scum Discharge

Accurate control over scum discharge is crucial for efficient waste management. The High Chromium Steel Scum Valve offers precise control mechanisms that allow operators to regulate the flow of scum with precision. This level of control ensures optimal disposal and prevents any potential damage to downstream equipment, guaranteeing a smooth and uninterrupted waste management process.

5. Environmentally Friendly Design for Sustainable Waste Disposal

Sustainability is a growing concern in waste management. The High Chromium Steel Scum Valve aligns with these environmental considerations with its eco-friendly design. The valve is engineered to minimize waste and reduce energy consumption, making it an eco-conscious choice for organizations striving to achieve sustainable waste disposal practices.

6. Enhanced Safety Features for Operator Protection

The safety of operators and maintenance personnel is of utmost importance in any industrial setting. The High Chromium Steel Scum Valve incorporates enhanced safety features to protect individuals working with the valve. From robust locking mechanisms to clear labeling and user-friendly controls, this valve prioritizes safety, ensuring a secure working environment for all.

The High Chromium Steel Scum Valve is a durable and corrosion-resistant solution for efficient waste management. With its seamless functionality, precise control, and versatile applications, this valve sets new standards in the industry. Discover its environmentally friendly design, enhanced safety features, and cost-effective benefits.

Certificates

Our manufacturing heavy industry expertise and commitment to quality have earned us a range of industry certificates, showcasing our dedication to excellence. With these certifications, we demonstrate our compliance with rigorous standards, ensuring that our products are of the highest quality and meet all necessary regulatory requirements. Our advantages lie not only in our certifications but also in our advanced production capabilities, state-of-the-art machinery, and skilled workforce. By leveraging cutting-edge technology and employing experienced professionals, we consistently deliver products that excel in performance, durability, and reliability. Additionally, our commitment to innovation allows us to stay ahead of the competition, constantly improving our processes and products to meet evolving market demands. With a strong emphasis on customer satisfaction, we strive to provide tailored solutions, prompt delivery, and exceptional after-sales service. Trust in our industry-leading expertise and certified products to gain a competitive edge in the manufacturing heavy industry.