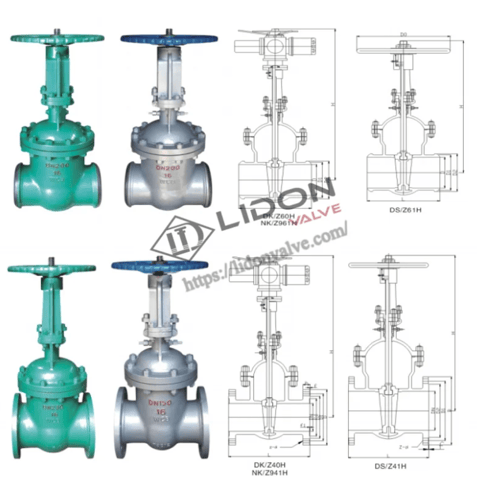

Water-sealed Gate Valve

Characteristics:

1. The water-sealed Gate Valve cover packing chamber has a water seal structure. When water with a pressure of 0.6~1.0MPa is introduced into the interface, the system can be isolated from the atmosphere and has good air tightness.

2. The selection of materials is superior to ordinary medium and low pressure valves. The pressure-bearing parts are made of cast steel, and the valve stem and sealing surface are made of stainless steel.

3. The Water-sealed Gate Valve has a parallel double gate structure, with reliable sealing, easy opening and closing, and easy maintenance.

4. The connection forms of this series of valves are divided into flange and welding. There are two ways of driving seeds: manual and electric.

Water-sealed Gate Valve

The water sealed gate valve is designed for the efficient control of pipelines with a nominal pressure of 100 MPa and operational temperatures reaching 425°C. This valve is well-suited for handling various working mediums, including water, steam, oil, and non-corrosive gases. It proves particularly effective in the vacuum condensing system of steam turbines within thermal power plants.

|

|

| Main dimension NK/Z61H、DK/Z60H、DS/Z61H、DS/Z961H |

||||||||||||||

| Nominal pressure CLASS |

Nominal diameter IN(mm) |

Nominal diameter DN(mm) |

Dimension(mm) | Weight(kg) | ||||||||||

| L | D | D | D1 | D1 | D2 | D2 | D0 | H | H1 | Manual operation | Power-driven | |||

| 300LB | 2 | 50 | 250 | 50 | 165 | 64 | 127 | 75 | 92 | 220 | 370 | 686 | 25 | 70 |

| 21/2 | 65 | 280 | 65 | 190 | 85 | 149.2 | 105 | 105 | 280 | 395 | 711 | 31 | 76 | |

| 3 | 80 | 310 | 80 | 210 | 105 | 168.3 | 125 | 127 | 300 | 450 | 766 | 40 | 90 | |

| 4 | 100 | 350 | 100 | 255 | 130 | 200 | 150 | 157 | 360 | 530 | 846 | 55 | 110 | |

| 5 | 125 | 400 | 125 | 280 | 155 | 235 | 185 | 186 | 360 | 627 | 943 | 89 | 144 | |

| 6 | 150 | 450 | 150 | 320 | 182 | 269.9 | 214 | 216 | 400 | 691 | 1007 | 110 | 168 | |

| 8 | 200 | 550 | 200 | 380 | 234 | 330.2 | 268 | 270 | 450 | 840 | 1156 | 200 | 358 | |

| 10 | 250 | 650 | 250 | 445 | 288 | 387.4 | 326 | 324 | 500 | 994 | 1409 | 301 | 411 | |

| 12 | 300 | 750 | 300 | 520 | 338 | 450.8 | 375 | 381 | 550 | 1172 | 1587 | 450 | 570 | |

| 14 | 350 | 850 | 350 | 585 | 392 | 514.4 | 430 | 413 | 600 | 1300 | 1753 | 610 | 749 | |

| 16 | 400 | 950 | 400 | 650 | 444 | 571.5 | 484 | 470 | 700 | 1502 | 1955 | 920 | 1062 | |

| 600LB | 2 | 50 | 250 | 50 | 165 | 74 | 127 | 98 | 92 | 320 | 375 | 691 | 32 | 82 |

| 21/2 | 65 | 280 | 65 | 190 | 89 | 149.2 | 113 | 105 | 360 | 410 | 726 | 40 | 97 | |

| 3 | 80 | 310 | 80 | 210 | 106 | 168.3 | 132 | 127 | 360 | 467 | 783 | 60 | 115 | |

| 4 | 100 | 350 | 100 | 275 | 132 | 215.9 | 165 | 157 | 400 | 557 | 873 | 80 | 138 | |

| 5 | 125 | 400 | 125 | 330 | 165 | 266.7 | 191 | 186 | 400 | 680 | 1095 | 135 | 245 | |

| 6 | 150 | 450 | 150 | 355 | 190 | 292.1 | 225 | 216 | 450 | 750 | 1165 | 200 | 320 | |

| 8 | 200 | 550 | 200 | 420 | 255 | 249.2 | 295 | 270 | 550 | 890 | 1029 | 330 | 469 | |

| 10 | 250 | 650 | 250 | 510 | 308 | 431.8 | 366 | 324 | 600 | 1080 | 1533 | 480 | 622 | |

| 12 | 300 | 750 | 300 | 560 | 354 | 489 | 391 | 381 | 700 | 1280 | 1865 | 750 | 1000 | |

| 14 | 350 | 850 | 350 | 605 | 412 | 527 | 450 | 413 | 700 | 1390 | 1975 | 980 | 1235 | |

| 16 | 400 | 950 | 400 | 685 | 466 | 603.2 | 506 | 470 | 800 | 1580 | 2297 | 1350 | 1700 | |

| Product classification |

Applicable medium |

Applicable temperature/℃ |

|||||||

| NKZ61H NKZ64H H-C type NKZ964H NKZ961H |

Water, Steam, Air | ≤425 | |||||||

| NKZ61H NKZ64H Y-1 type NKZ964H NKZ961H |

Water, Steam, Air | ≤550 | |||||||

| PN/MPa Nominal pressure |

Seal test/MPa | |||||||

| Shell strength | Back seal | Seal test | ||||||

| 2.5 | 3.8 | 2.8 | 2.8 | |||||

| 4.0 | 6.0 | 4.4 | 4.4 | |||||

| 6.4 | 9.6 | 7.0 | 7.0 | |||||

| 10.0 | 15.0 | 11.0 | 11.0 | |||||

| Part name |

Body Bonnet |

Valve stem |

Wedge gate | Sealing face |

Valve Yoke nut |

Packing | Fastener | |||||||

| NKZ64 NKZ61 H-C type NKZ964 NKZ961 |

WCB | 2Cr13 | 25 | H: alloy steel | Al bronze | Expanding compound graphite |

High-grade carbon steel |

|||||||

| NKZ64 NKZ61 Y-Itype NKZ964 NKZ961 |

Cr. Mo steel | 20Cr1MoIVA | Cr. Mo steel | Y: carbide alloy |

Cr. Mo steel | |||||||||

Efficient Flow Control for Optimal System Performance

With its precise flow control capabilities, the Water-sealed Gate Valve allows you to achieve optimal system performance. The valve features a gate mechanism that can be easily opened or closed to regulate the flow of fluids. This allows you to control the flow rate and pressure with precision, ensuring efficient operation of your fluid handling system.

Wide Range of Sizes and Configurations

With a wide range of sizes and configurations available, the Water-sealed Gate Valve can accommodate various system requirements. Whether you need a compact valve for limited spaces or a larger one for high-flow applications, there is a suitable option for every need. The valve's versatility makes it a versatile choice for industries such as oil and gas, water treatment, and chemical processing.

Smooth Operation with Minimal Friction

The Water-sealed Gate Valve is designed for smooth and efficient operation. Its gate mechanism moves smoothly within the valve body, minimizing friction and reducing wear and tear. This not only ensures reliable performance but also extends the lifespan of the valve, saving you money on frequent replacements.

Excellent Pressure and Temperature Resistance

Operating in high-pressure and high-temperature environments can be challenging for valves. However, the Water-sealed Gate Valve is specifically engineered to withstand extreme conditions. Its robust construction and high-pressure sealing capability make it suitable for demanding applications where other valves may fail.

Suitable for Various Fluids

Whether you are handling water, oil, gas, or other fluids, the Water-sealed Gate Valve is up to the task. Its versatile design and compatibility with a wide range of fluids make it a reliable choice for diverse applications. From industrial processes to residential plumbing systems, this valve ensures efficient and controlled fluid flow.

Cost-effective Solution for Fluid Control

The Water-sealed Gate Valve offers a cost-effective solution for fluid control. Its durable construction, minimal maintenance requirements, and long lifespan make it a wise investment. By choosing this valve, you can achieve optimal flow control while minimizing downtime and reducing overall operating costs.

Water-sealed Gate Valve, valve, flow control, reliable, durable, efficient, precise, installation, maintenance, leak-proof, safety, sizes, configurations, smooth operation, friction, pressure resistance, temperature resistance, fluids, cost-effectiveWater-sealed Gate Valve: Ensuring Reliable Flow ControlThe Water-sealed Gate Valve is a top-notch choice for efficient fluid management. With its precise flow control capabilities, leak-proof design, and wide range of sizes, this valve ensures reliable performance in various industries.

Certificates

Our manufacturing heavy industry expertise and commitment to quality have earned us a range of industry certificates, showcasing our dedication to excellence. With these certifications, we demonstrate our compliance with rigorous standards, ensuring that our products are of the highest quality and meet all necessary regulatory requirements. Our advantages lie not only in our certifications but also in our advanced production capabilities, state-of-the-art machinery, and skilled workforce. By leveraging cutting-edge technology and employing experienced professionals, we consistently deliver products that excel in performance, durability, and reliability. Additionally, our commitment to innovation allows us to stay ahead of the competition, constantly improving our processes and products to meet evolving market demands. With a strong emphasis on customer satisfaction, we strive to provide tailored solutions, prompt delivery, and exceptional after-sales service. Trust in our industry-leading expertise and certified products to gain a competitive edge in the manufacturing heavy industry.