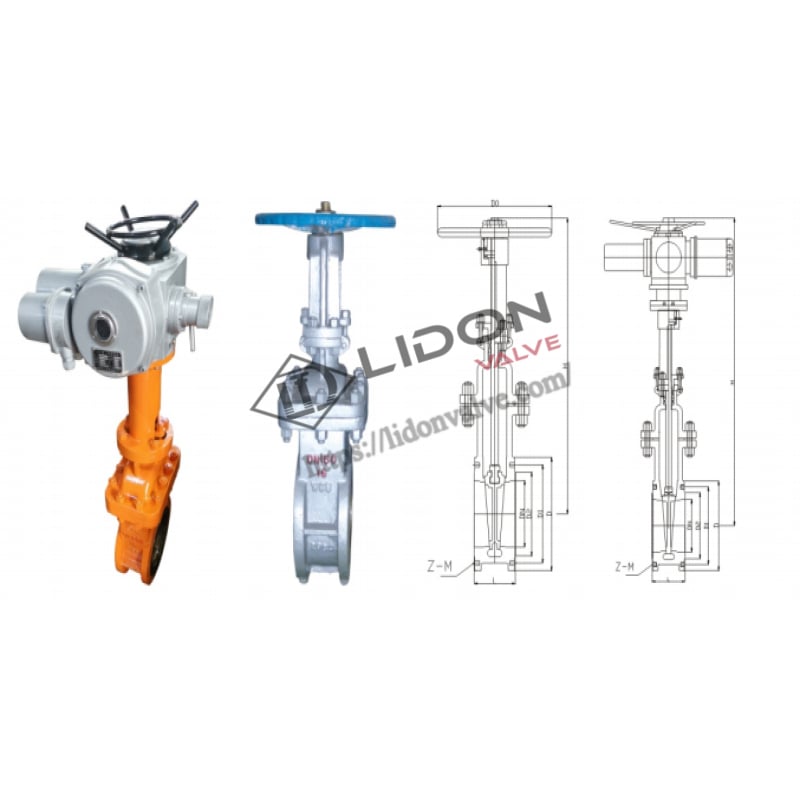

Two-phase Flow Gate Valve

Characteristics:

1. The working principle of the closing part of the two-phase flow wafer type slag discharge gate valve is the same as that of other ordinary gate valves, and its valve disc is a wedge structure.

2. It is different from the Z41H gate valve in that the inlet and outlet distance is shorter, the connection method adopts a clamping type, and the slag-water mixture slag-water ratio is ≤1:6 for the largest particles. This product is suitable for water ash removal and dry ash removal in thermal power plants. system.

3. The valve cover and the branch frame of this valve are connected in a separate manner and are operated by a handwheel in an open-rod structure. The shape and structure of this valve are similar to that of American standard flat gate valve.

4. This product is used as an opening and closing device on two-phase flow pipelines in the mining industry and other industries, where it cannot be used for adjustment or throttling, and where the frequency of opening and closing is low.

| Nominal pressure CLASS |

Nominal diameter IN(mm) |

L | D | D1 | D2 | Z-M | D | H | |

| Manual operation | power-driven | ||||||||

| 150LB | 2 | 100 | 152 | 120.5 | 92 | 4-M16 | 280 | 320 | 470 |

| 21/2 | 100 | 178 | 139.5 | 105 | 4-M16 | 280 | 390 | 560 | |

| 3 | 110 | 190 | 152.5 | 127 | 8-M16 | 280 | 478 | 660 | |

| 4 | 120 | 229 | 190.5 | 157 | 8-M16 | 320 | 549 | 730 | |

| 5 | 130 | 254 | 216 | 186 | 8-M16 | 320 | 798 | 925 | |

| 9 | 140 | 279 | 241.5 | 216 | 8-M20 | 320 | 849 | 1200 | |

| 8 | 150 | 343 | 298.5 | 270 | 12-M24 | 360 | 890 | 1280 | |

| 10 | 150 | 406 | 362 | 324 | 12-M24 | 360 | 950 | 1390 | |

| 12 | 180 | 483 | 432 | 381 | 12-M24 | 400 | 1000 | 1500 | |

| 14 | 200 | 534 | 476.5 | 413 | 16-M24 | 400 | 1110 | 1450 | |

| 16 | 230 | 597 | 539.5 | 470 | 16-M27 | 450 | 1190 | 1650 | |

| 18 | 250 | 635 | 578 | 533 | 20-M27 | 560 | 1260 | 1800 | |

| 20 | 250 | 699 | 635 | 584 | 20-M30 | 560 | 1330 | 1900 | |

| 300LB | 2 | 110 | 165 | 127 | 92 | 4-M16 | 280 | 320 | |

| 21/2 | 115 | 190 | 149.2 | 105 | 4-M16 | 280 | 390 | ||

| 3 | 125 | 210 | 168.3 | 127 | 8-M16 | 280 | 478 | ||

| 4 | 130 | 255 | 200 | 157 | 8-M20 | 320 | 549 | ||

| 5 | 150 | 280 | 235 | 186 | 8-M24 | 320 | 798 | ||

| 6 | 150 | 320 | 269.9 | 216 | 8-M24 | 360 | 849 | ||

| 8 | 160 | 380 | 330.2 | 270 | 12-M27 | 360 | 950 | ||

| 10 | 180 | 445 | 387.4 | 324 | 12-M30 | 400 | 1000 | ||

| 12 | 210 | 520 | 450.8 | 381 | 16-M30 | 400 | 1000 | ||

| 14 | 230 | 585 | 514.4 | 413 | 16-M33 | 560 | 1190 | ||

| 16 | 270 | 650 | 571.5 | 470 | 16-M33 | 560 | 1260 | ||

| 18 | 290 | 710 | 628.6 | 533 | 20-M36 | 720 | 1310 | ||

| 20 | 310 | 775 | 685.8 | 584 | 20-M39 | 720 | 1330 | ||

| type | Nominal pressure MPa | Strength test pressure MPa |

Operating temperature℃ | Applicable media | |||

| LXLZ | 971 71 |

-10C | 1.0 | 1.5 | ≤400 | Slag water mixture Residue to water ratio≤1:6 maximum granularity≤50mm |

|

| LXLZ | 971 71 |

-16C | 1.6 | 2.4 | |||

| LXLZ | 971 71 |

-25 | 2.5 | 3.8 | |||

| LXLZ | 971 71 |

-40C | 4.0 | 6.0 | |||

| Material for main parts | ||||||

| Part Name | Material | |||||

| 10C | 16C | 25 | 40 | |||

| valve body | WCB | |||||

| cap | WCB | |||||

| gate | WCB+85CrMn(Overlay welding) | |||||

| Stem | 2Cr13Stainless steel | |||||

| Stem nut | cast steel bronze | |||||

Introducing our innovative Two-phase Flow Gate Valve, a game-changing solution for controlling and regulating the flow of fluids in complex industrial processes. With its advanced design and cutting-edge technology, this valve offers unparalleled efficiency, reliability, and performance. Whether you are in the oil and gas, chemical, or power generation industry, our Two-phase Flow Gate Valve is the ideal choice for optimizing your operations.

Exceptional Flow Control

Designed to handle two-phase flow, this gate valve provides exceptional control over the flow rate, pressure, and direction of fluids. Its robust construction and precise engineering ensure smooth and efficient operation even in high-pressure and high-temperature applications. By effectively managing the flow of both liquid and gas phases, this valve minimizes the risk of fluid instability, cavitation, and other flow-related issues, resulting in improved process efficiency and reduced operational costs.

Reliability and Durability

Our Two-phase Flow Gate Valve is built to withstand the most demanding industrial environments. Constructed from high-quality materials such as stainless steel and specially engineered alloys, this valve offers exceptional durability, corrosion resistance, and longevity. Its rugged design and advanced sealing mechanisms ensure leak-proof operation, preventing costly downtime and enhancing the overall reliability of your system.

Easy Installation and Maintenance

Installing and maintaining our Two-phase Flow Gate Valve is a breeze. With its compact design and user-friendly features, this valve can be easily integrated into existing pipeline systems. The valve's modular construction allows for quick and hassle-free maintenance, minimizing downtime and reducing operational disruptions. Additionally, our valve is equipped with advanced diagnostic capabilities, enabling proactive maintenance and troubleshooting.

Enhanced Safety Features

Our top priority is safety, and our Two-phase Flow Gate Valve is designed with a range of safety features to ensure the well-being of your personnel and assets. The valve incorporates advanced pressure relief and anti-cavitation mechanisms, preventing sudden pressure surges and flow instabilities. Moreover, the valve's fail-safe design and emergency shut-off capabilities provide an added layer of protection, allowing for quick and efficient response in critical situations.

Versatile Applications

Our Two-phase Flow Gate Valve is suitable for a wide range of applications across various industries. From oil and gas production to chemical processing and power generation, this valve can effectively handle the unique challenges presented by two-phase flow. Its versatility allows for seamless integration into different systems, ensuring optimal performance and reliability in any operating environment.

Customizable Solutions

We understand that every industry and application has specific requirements. That's why our Two-phase Flow Gate Valve is available in a range of configurations and sizes to suit your unique needs. Whether you require specific materials, connection types, or operating parameters, our team of experts can work with you to provide tailor-made solutions that meet your exact specifications.

Certificates

Our manufacturing heavy industry expertise and commitment to quality have earned us a range of industry certificates, showcasing our dedication to excellence. With these certifications, we demonstrate our compliance with rigorous standards, ensuring that our products are of the highest quality and meet all necessary regulatory requirements. Our advantages lie not only in our certifications but also in our advanced production capabilities, state-of-the-art machinery, and skilled workforce. By leveraging cutting-edge technology and employing experienced professionals, we consistently deliver products that excel in performance, durability, and reliability. Additionally, our commitment to innovation allows us to stay ahead of the competition, constantly improving our processes and products to meet evolving market demands. With a strong emphasis on customer satisfaction, we strive to provide tailored solutions, prompt delivery, and exceptional after-sales service. Trust in our industry-leading expertise and certified products to gain a competitive edge in the manufacturing heavy industry.