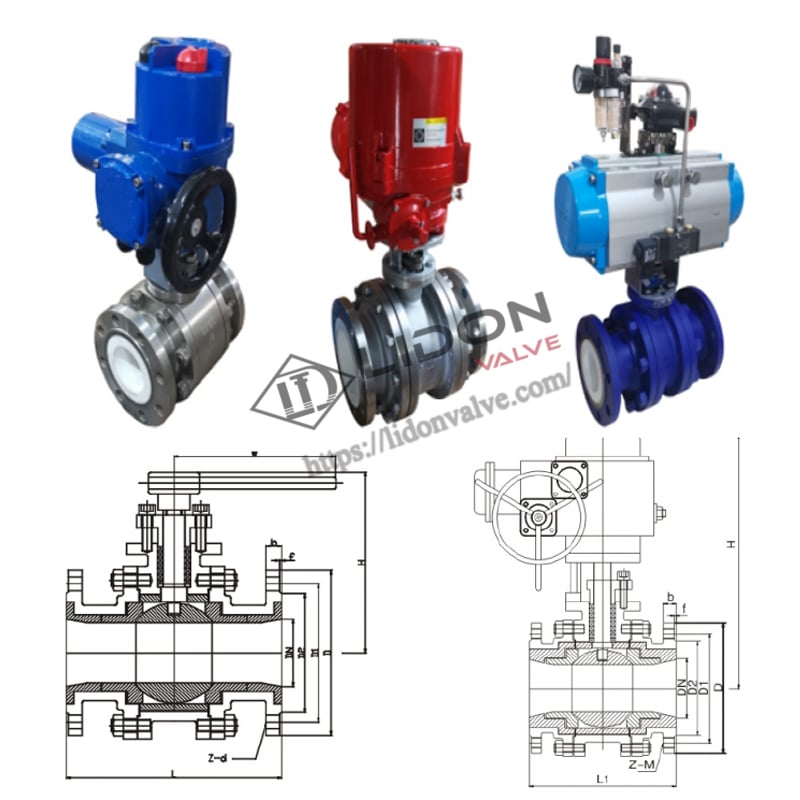

Electric Ceramic Lined Ball Valve

Characteristics:

1. All parts in contact with the medium are structural ceramic materials with extremely high chemical stability and hardness (Rockwell hardness HRC90), second only to diamond. Therefore, this valve has extremely high wear resistance, corrosion resistance, and erosion resistance, as well as good heat insulation and small thermal expansion.

2. The ball is manufactured using advanced grinding equipment and processes, with high roundness accuracy and good surface quality. After grinding with the valve seat, the self-lubricating property of Zr02 ceramic can be used to achieve good sealing performance.

3. The good wear resistance of ceramic makes this valve durable, extremely reliable, and has a long service life, which is 2-4 times that of titanium alloy valves and Monel valves.

4. When used in granular media with high hardness, or media with soft particles but corrosiveness, this valve has unparalleled absolute advantages and is currently the only valve suitable for such media.

| Nominal pressure CLASS |

Nominal diameter IN(mm) |

Dimension(mm) | Weight (kg) |

|||||||||

| L | L1 | D | D1 | D2 | b | f | Z-d | W | H | |||

| 150LB | 2 | 200 | 175 | 152 | 120.5 | 92 | 19 | 2 | 4-19 | 250 | 160 | 18 |

| 21/2 | 220 | 190 | 178 | 139.5 | 105 | 22.5 | 2 | 4-19 | 300 | 172 | 23 | |

| 3 | 250 | 203 | 190 | 152.5 | 127 | 23.9 | 2 | 4-19 | 350 | 189 | 31 | |

| 4 | 280 | 229 | 229 | 190.5 | 157 | 23.9 | 2 | 8-19 | 500 | 200 | 38 | |

| 5 | 320 | 254 | 254 | 216 | 186 | 23.9 | 2 | 8-22 | 500 | 228 | 65 | |

| 9 | 360 | 267 | 279 | 241.5 | 216 | 25.4 | 2 | 8-22 | 800 | 270 | 95 | |

| 8 | 400 | 292 | 343 | 298.5 | 270 | 28.5 | 2 | 8-22 | 800 | 295 | 125 | |

| 10 | 533 | 330 | 406 | 362 | 324 | 31 | 2 | 12-25 | 1000 | 395 | 215 | |

| 12 | 610 | 356 | 483 | 432 | 381 | 32 | 2 | 12-25 | 1100 | 445 | 300 | |

| valve body | Stem | sphere | valve seat | filler | Applicable media | Suitable Temperature |

||||||

| WCB | 2Cr13 | Complex Ceramics | Complex Ceramics | PTFE | Coal powder, cinder, powdery particles, etc. corrosive media | ≤200℃ | ||||||

| CF8 304 |

0Cr18Ni9 (304) |

Complex Ceramics | Complex Ceramics | PTFE | Coal powder, cinder, powdery particles, Corrosive media such as urea |

≤200℃ | ||||||

| CF8M 316 |

0Cr17Ni12M02 (316) |

Complex Ceramics | Complex Ceramics | PTFE | Coal powder, cinder, powdery particles, Corrosive media such as nitric acid |

≤200℃ | ||||||

| CF3M 316L |

00Cr17Ni14Mo2 (316L) |

Complex Ceramics | Complex Ceramics | PTFE | Coal powder, cinder, powdery particles, Corrosive media such as acetic acid |

≤200℃ | ||||||

| Design reference | GB | API | ASME | |||||

| Design standard | GB/T12237 | API 6D | ASME B16.34 | |||||

| Structural length | GB/T12221 | API 6D | ASME B16.10 | |||||

| Flanged ends | GB/T9113 JB/T79 |

ASME B16.5、B16.47 | ||||||

| Test & inspection | JB/T9092 | API 6D | API 598 | |||||

| Nominal pressure PN |

Working pressure under normal temperature Max. |

The shell testing | Air seal test pressure | High-pressure seal test pressure |

||||

| 1.6 | 1.6 | 2.4 | 0.6 | 1.76 | ||||

| 2.5 | 2.5 | 3.8 | 0.6 | 2.75 | ||||

| 4.0 | 4.0 | 6.0 | 0.6 | 4.4 | ||||

| 6.4 | 6.4 | 9.6 | 0.6 | 7.1 | ||||

| Class150 | 2.0 | 3.0 | 0.6 | 2.2 | ||||

| Class300 | 5.0 | 7.5 | 0.6 | 5.5 | ||||

Introducing the Electric Ceramic Lined Ball Valve: The Perfect Solution for Reliable and Efficient Flow Control

Electric Ceramic Lined Ball Valve: The Ultimate Choice for Reliable Flow Control Experience unrivaled performance with our Electric Ceramic Lined Ball Valve. Designed for efficient flow control, this valve ensures reliability and durability. Discover how this product can revolutionize your operations. Electric Ceramic Lined Ball Valve, flow control, reliable, efficient, performance, durability

Unmatched Durability with Ceramic Lining

Our Electric Ceramic Lined Ball Valve features a state-of-the-art ceramic lining that offers exceptional resistance to corrosion, erosion, and wear. This advanced ceramic material provides superior protection against harsh substances, ensuring long-lasting performance even in the most demanding applications. Say goodbye to frequent valve replacements and enjoy peace of mind knowing that your flow control system is built to withstand the test of time.

Precise Flow Control with Electric Actuation

Equipped with an electric actuator, our Electric Ceramic Lined Ball Valve allows for precise control over the flow of various substances. The actuator ensures quick and accurate adjustments, eliminating the need for manual intervention. With its smooth and reliable operation, this valve guarantees optimal efficiency in your processes, saving you time and resources.

Seamless Integration with Existing Systems

The Electric Ceramic Lined Ball Valve is designed to seamlessly integrate into your existing flow control systems. With its standard flange connection, installation is a breeze, and compatibility is ensured. Whether you need to replace an old valve or upgrade your system, this valve provides a hassle-free solution that minimizes downtime and maximizes productivity.

Efficient Energy Consumption

Our Electric Ceramic Lined Ball Valve is engineered to optimize energy consumption. The electric actuator utilizes power only when necessary, reducing energy waste and lowering operational costs. Enjoy the benefits of an eco-friendly valve that not only enhances performance but also contributes to a sustainable future.

Safe and Reliable Operation

Safety is paramount in any industrial setting, and our Electric Ceramic Lined Ball Valve prioritizes it. With its fail-safe design, this valve ensures that in the event of a power failure, it automatically returns to a predetermined position, maintaining process integrity. Additionally, the ceramic lining prevents leaks and minimizes the risk of accidents, guaranteeing a safe and reliable operation.

Minimal Maintenance Requirement

With our Electric Ceramic Lined Ball Valve, maintenance becomes a breeze. The ceramic lining eliminates the need for frequent cleaning and inspection, as it resists buildup and scaling. The valve's robust construction and durable materials reduce the risk of breakdowns, minimizing maintenance efforts and maximizing uptime.

Wide Range of Applications

Our Electric Ceramic Lined Ball Valve is suitable for a wide range of applications across industries. From chemical processing and power generation to water treatment and oil refining, this valve excels in handling corrosive and abrasive substances. Its versatility makes it a reliable choice for various flow control needs, ensuring optimal performance in diverse environments.

Superior Control in Extreme Conditions

Extreme temperatures and harsh operating conditions are no match for our Electric Ceramic Lined Ball Valve. The ceramic lining provides excellent thermal insulation, allowing the valve to withstand high temperatures without compromising its performance. Whether you're dealing with extreme heat or extreme cold, this valve guarantees superior control and reliability.

Enhanced Efficiency with Low Fugitive Emissions

Our Electric Ceramic Lined Ball Valve offers low fugitive emissions, ensuring compliance with environmental regulations and promoting a healthier workplace. The ceramic lining prevents leaks, reducing the escape of harmful substances and minimizing the impact on the environment. Experience enhanced efficiency and a cleaner working environment with our environmentally conscious valve.

Uncompromised Performance with Longevity

Invest in the Electric Ceramic Lined Ball Valve and enjoy uncompromised performance coupled with exceptional longevity. This valve is built to exceed industry standards, providing reliable flow control for years to come. With its robust construction, advanced ceramic lining, and cutting-edge technology, this valve sets the benchmark for durability and performance in the world of flow control.

Certificates

Our manufacturing heavy industry expertise and commitment to quality have earned us a range of industry certificates, showcasing our dedication to excellence. With these certifications, we demonstrate our compliance with rigorous standards, ensuring that our products are of the highest quality and meet all necessary regulatory requirements. Our advantages lie not only in our certifications but also in our advanced production capabilities, state-of-the-art machinery, and skilled workforce. By leveraging cutting-edge technology and employing experienced professionals, we consistently deliver products that excel in performance, durability, and reliability. Additionally, our commitment to innovation allows us to stay ahead of the competition, constantly improving our processes and products to meet evolving market demands. With a strong emphasis on customer satisfaction, we strive to provide tailored solutions, prompt delivery, and exceptional after-sales service. Trust in our industry-leading expertise and certified products to gain a competitive edge in the manufacturing heavy industry.