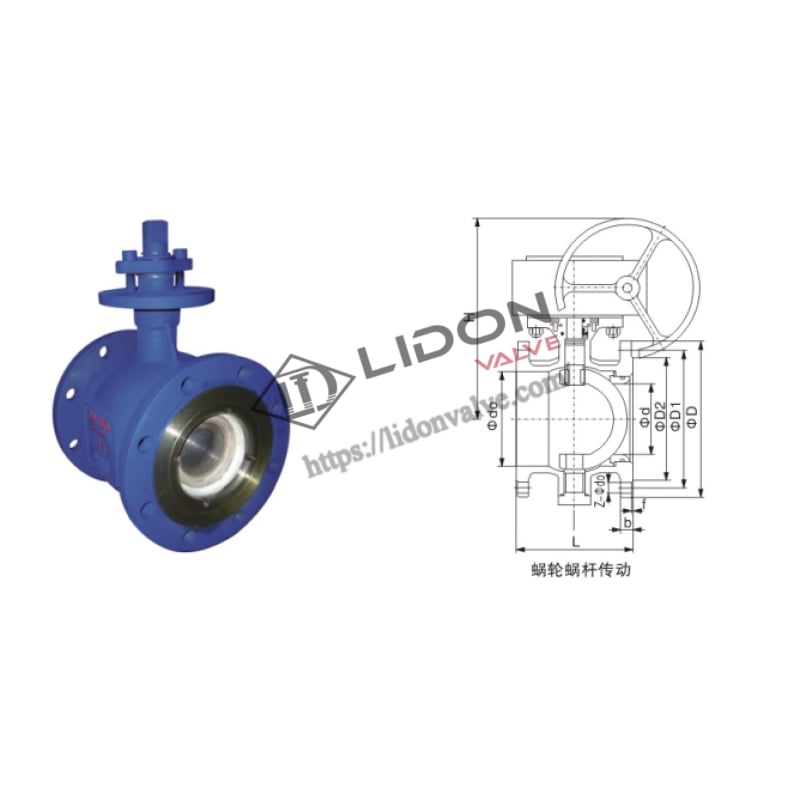

Ceramic Semi Ball Valve

Characteristics:

1. Good wear resistance: The valve seat and hemisphere made of ceramic materials have excellent wear resistance and can be used for a long time without being easily worn. They are suitable for some media containing solid particles;

2. Excellent sealing performance: The contact surface between the ceramic valve seat and the hemisphere forms a highly precise fit, giving the valve good sealing performance and effectively preventing medium leakage;

3. Long life: Due to the wear resistance and chemical stability of ceramic materials, ceramic semi-ball valves have a long service life, which can reduce the frequency of valve replacement and maintenance costs;

4. Strong corrosion resistance: Ceramic materials have good chemical stability can resist the erosion of most corrosive media, and are suitable for handling some corrosive media such as strong acids and strong alkalis;

5. Small fluid resistance: The ceramic material has a smooth surface and small friction resistance, which can reduce the resistance and pressure drop when the fluid passes through the valve.

| Nominal pressure CLASS |

Nominal diameter IN(mm) |

Nominal diameter IN(mm) |

Dimension(mm) | Weight (kg) |

||||||||||

| L | d | D | D1 | D2 | b | f | Z-do | H | ||||||

| Manual operation | Worm gear | Manual operation | Worm gear | |||||||||||

| 150LB | 2 | 50 | 178 | 38 | 152 | 120.5 | 92 | 19 | 2 | 4-18 | 225 | 248 | 21 | 30 |

| 21/2 | 65 | 190 | 51 | 178 | 139.5 | 105 | 22.5 | 2 | 4-18 | 235 | 255 | 24 | 33 | |

| 3 | 80 | 203 | 64 | 190 | 152.5 | 127 | 23.9 | 2 | 8-18 | 260 | 270 | 34 | 42 | |

| 4 | 100 | 229 | 76 | 229 | 190.5 | 157 | 23.9 | 2 | 8-18 | 270 | 278 | 47 | 55 | |

| 5 | 125 | 254 | 102 | 254 | 216 | 186 | 23.9 | 2 | 8-18 | 320 | 335 | 57 | 64 | |

| 9 | 150 | 264 | 127 | 279 | 241.5 | 216 | 25.4 | 2 | 8-23 | 340 | 358 | 79 | 86 | |

| 8 | 200 | 292 | 152 | 343 | 298.5 | 270 | 28.5 | 2 | 12-23 | 390 | 405 | 105 | 117 | |

| 10 | 250 | 330 | 203 | 406 | 362 | 324 | 31 | 2 | 12-25 | 420 | 449 | 144 | 169 | |

| 12 | 300 | 356 | 254 | 483 | 432 | 381 | 32 | 2 | 12-25 | 510 | 550 | 186 | 231 | |

| 14 | 350 | 381 | 266 | 534 | 476.5 | 413 | 35 | 2 | 16-25 | 555 | 600 | 220 | 280 | |

| 16 | 400 | 406 | 303 | 597 | 539.5 | 470 | 37 | 2 | 16-30 | 610 | 670 | 260 | 300 | |

High-Quality Ceramic Semi Ball Valve for Efficient Flow Control

A Ceramic Semi Ball Valve is an essential component used in various industries for efficient flow control. This high-quality valve offers exceptional performance and durability, making it an ideal choice for a wide range of applications. With its innovative design and advanced features, this valve ensures optimal functioning and long-lasting service.

Precision Control and Smooth Operation

The Ceramic Semi Ball Valve is designed for precision control and smooth operation. Its semi-ball design allows for precise flow control, enabling users to regulate the flow rate accurately. The valve's smooth operation ensures minimal friction and pressure drop, resulting in efficient fluid flow and reduced energy consumption.

Leak-proof and Reliable Performance

With its robust construction and tight sealing mechanism, this Ceramic Semi Ball Valve offers leak-proof and reliable performance. The valve's sealing surfaces are precision-machined to ensure a tight seal, preventing any leakage or loss of fluid. This reliability makes the valve suitable for critical applications where any leakage can have severe consequences.

Wide Temperature and Pressure Range

The Ceramic Semi Ball Valve is designed to operate within a wide temperature and pressure range, making it suitable for diverse industrial applications. It can withstand high temperatures and pressures without compromising its performance or integrity. This versatility allows the valve to be used in various industries, including chemical, oil and gas, and power generation.

Compact and Space-saving Design

The Ceramic Semi Ball Valve features a compact and space-saving design, making it suitable for installations where space is limited. Its compact size allows for easy integration into existing systems or tight spaces without compromising performance. This design feature ensures maximum utilization of available space and enhances overall system efficiency.

Versatile and Compatible with Various Media

This Ceramic Semi Ball Valve is versatile and compatible with a wide range of media, including liquids, gases, and slurries. It can handle different types of fluids without compromising its performance or integrity. This versatility makes the valve suitable for applications in industries such as water treatment, chemical processing, and pharmaceuticals.

Industry-standard Certifications and Compliance

This Ceramic Semi Ball Valve meets industry-standard certifications and compliance, ensuring its reliability and safety. It undergoes rigorous testing and quality control measures to meet the highest industry standards. This certification gives users confidence in the valve's performance and guarantees its suitability for even the most demanding applications.

Certificates

Our manufacturing heavy industry expertise and commitment to quality have earned us a range of industry certificates, showcasing our dedication to excellence. With these certifications, we demonstrate our compliance with rigorous standards, ensuring that our products are of the highest quality and meet all necessary regulatory requirements. Our advantages lie not only in our certifications but also in our advanced production capabilities, state-of-the-art machinery, and skilled workforce. By leveraging cutting-edge technology and employing experienced professionals, we consistently deliver products that excel in performance, durability, and reliability. Additionally, our commitment to innovation allows us to stay ahead of the competition, constantly improving our processes and products to meet evolving market demands. With a strong emphasis on customer satisfaction, we strive to provide tailored solutions, prompt delivery, and exceptional after-sales service. Trust in our industry-leading expertise and certified products to gain a competitive edge in the manufacturing heavy industry.