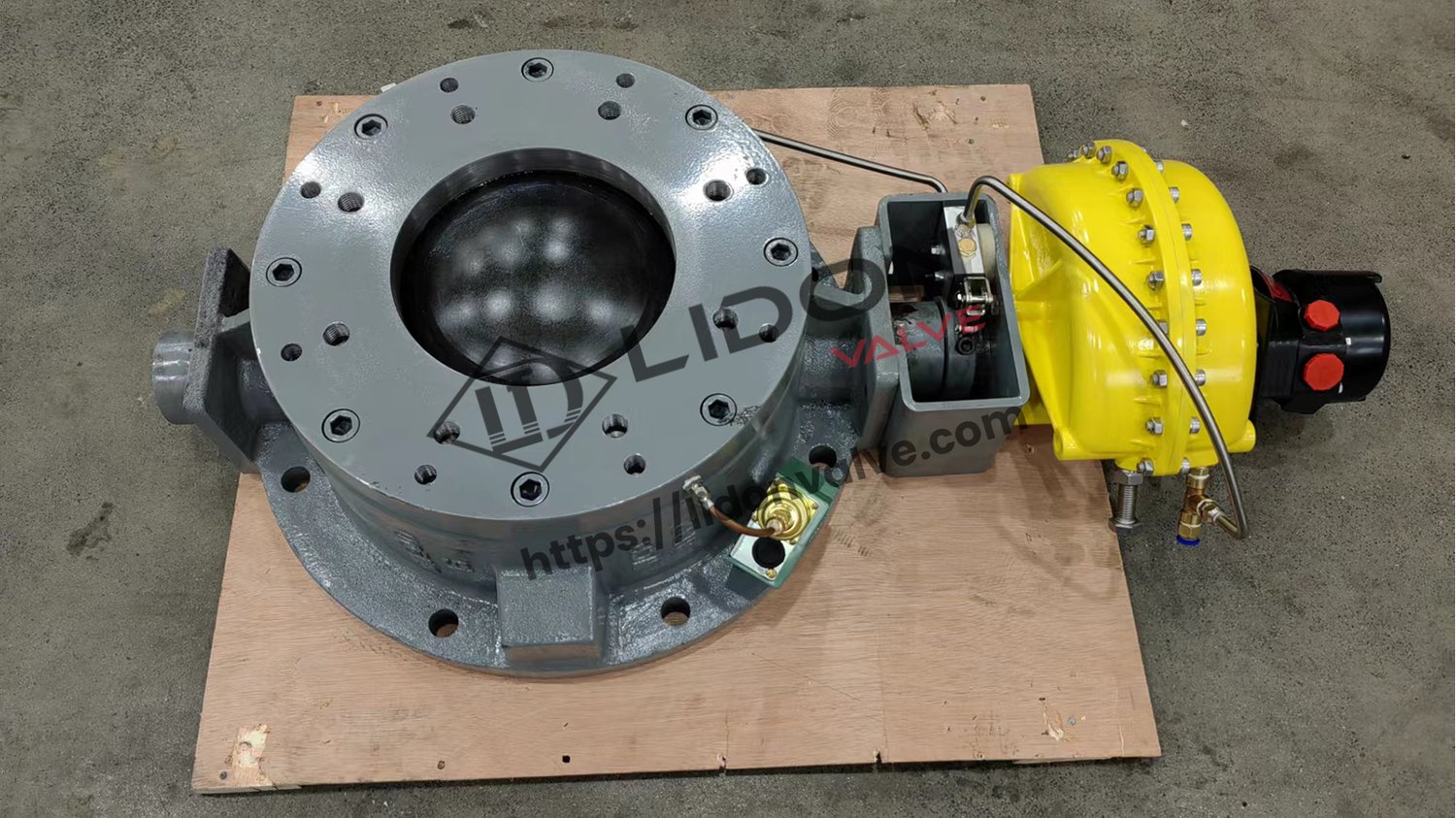

A dome valve: An essential component in industrial systems

A dome valve is a specialized type of valve that is commonly used in various industrial applications. It is designed to control the flow of materials, such as powders, granules, and other solid substances. In this article, we will explore the purpose and functionality of a dome valve, as well as its advantages and applications in different industries.

Understanding the working principle of a dome valve

A dome valve operates on a unique principle that sets it apart from conventional valves. Unlike traditional valves that rely on a sliding or rotating mechanism to control the flow, a dome valve utilizes a dome-shaped diaphragm to regulate the material flow. When the valve is closed, the dome-shaped diaphragm seals against the valve seat, preventing any material from passing through. When the valve is opened, the dome-shaped diaphragm flexes and allows the material to flow freely.

The purpose of a dome valve in material handling

Dome valves are specifically designed to handle abrasive and difficult-to-handle materials. Their purpose is to provide reliable and efficient flow control in industries where the handling of such materials is necessary. The dome-shaped diaphragm offers enhanced resistance to wear and tear, making it ideal for handling abrasive substances. Additionally, the unique design of the dome valve minimizes the risk of material clogging or jamming, ensuring smooth and uninterrupted material flow.

Advantages of using a dome valve

There are several advantages to using dome valves in industrial systems:

- Improved material flow control: Dome valves offer precise and reliable control over the flow of materials, allowing for better process efficiency.

- Reduced maintenance: The dome-shaped diaphragm of a dome valve is highly resistant to wear and tear, resulting in reduced maintenance and downtime.

- Minimized risk of clogging: The design of the dome valve minimizes the risk of material clogging or jamming, ensuring uninterrupted flow and preventing costly disruptions.

- Suitable for abrasive materials: Dome valves are specifically designed to handle abrasive materials, making them an excellent choice for industries dealing with such substances.

- Long service life: Due to their robust construction and wear-resistant materials, dome valves have a long service life, providing reliable performance over an extended period.

Applications of dome valves in different industries

Dome valves find application in various industries that deal with the handling of abrasive materials. Some of the key industries where dome valves are commonly used include:

- Mining and minerals: Dome valves are essential in mining operations for controlling the flow of ores, minerals, and other abrasive materials.

- Chemical processing: Chemical plants often use dome valves for handling granules, powders, and other abrasive substances in their production processes.

- Power generation: Dome valves play a crucial role in power plants for controlling the flow of coal, ash, and other materials used in the combustion process.

- Food and beverage: In the food and beverage industry, dome valves are employed for handling powdered ingredients, such as flour, sugar, and spices.

- Cement and construction: Dome valves are widely used in cement plants and construction sites for controlling the flow of cement, sand, and other construction materials.

Conclusion

Dome valves are an integral part of industrial systems that require precise and efficient flow control of abrasive materials. Their unique design and functionality make them ideal for handling challenging substances and minimizing the risk of clogging or jamming. With their numerous advantages and wide range of applications in various industries, dome valves continue to play a crucial role in ensuring smooth operations and enhanced productivity.